If you are looking for a way to adjust your wera torque screwdriver, there are a few things that you will need to do. First, you will need to find the correct size wrench that fits the screwdriver. Next, you will need to find the correct setting on the screwdriver. Finally, you will need to tighten or loosen the screwdriver until it is at the correct torque.

To adjust the torque of your Wera Torque Screwdriver, first make sure that the tool is set to the ” clutch ” position. Then, use the torque adjustment knob to set the desired torque. Once the correct torque is set, you can use the tool like a regular screwdriver.

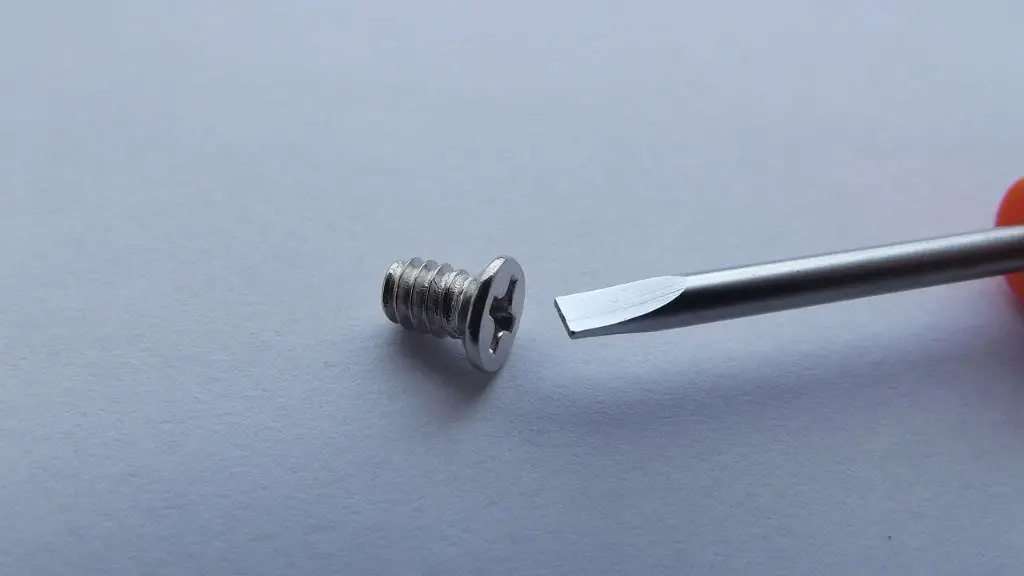

How do you adjust a torque screwdriver?

To adjust the torque setting on a preset torque screwdriver, remove the end cap. To increase the torque setting, loosen the lock screw. Insert the hex key into the internal adjuster and turn clockwise. To decrease the setting, rotate counterclockwise below your desired setting.

It’s important to keep your torque tools in good condition by regularly calibrating them. This will help ensure consistent performance and accuracy, and will help avoid any potential safety issues.

How do you use a Wera screwdriver

This is a note about a screwdriver set. The set is designed to 04 Newton meters. The note explains how to use the set.

Depending on the torque hit the first Time turn clockwise to increase the torque or turn counterclockwise to decrease the torque.

How do you adjust torque settings?

The torque setting on a wrench can be adjusted by turning the bar clockwise. This will increase the amount of torque that is applied to the wrench, making it easier to hold the wrench steady.

It is important to follow the instructions when tightening a bolt. In this case, you should turn the bolt clockwise until it locks in place. This will ensure that the torque specification is met and that the bolt will not come loose.

Where can I get a torque screwdriver calibrated?

Torque calibration laboratories are specialized facilities that are equipped to calibrate all types of torque tools, including torque multipliers and torque transducers. These laboratories typically have capacities of up to 35,000 pound-feet (lb ft) and can measure up to 20,000 lb ft of torque. While there are a number of torque calibration laboratories located throughout the country, it is important to choose one that is reputable and has a good track record.

If you’re looking for a single torque wrench that operates in the 1-25 N-m range, this is it. I use this on several MTB bicycles and it really removes any probability of me over/under tightening. You simply dial in to the decimal in either inch-lb or N-m and click you’re done.

How do you calibrate torque tools

When changing a tyre, it is important to get the torque wrench as parallel to the ground as possible. This will ensure that the tyre is tight and won’t come loose.

Overall, we really like Wera screwdrivers. They’re comfortable to hold, they have some really nice features, and there’s a good range of options to choose from. That said, there are still some areas where they could improve, but on the whole, they’re still ahead of the competition. If you haven’t tried them yet, we recommend you do – you won’t be disappointed.

Are Williams screwdrivers the same as snap-on?

The rebranding was announced by Snap-on in a press release, with the company saying that the move will help it better connect with customers and communicate the full range of products available under the Williams brand.

The Williams brand has been associated with high-quality, durable tools since 1882, and Snap-on says that the rebranding will help it tap into that rich history and tradition.

Snap-on says that the name change will be accompanied by a new logo and visual identity for the Williams brand, which will begin rolling out in the coming weeks.

The Wera 05051610001 Kraftform 819/1 Hexagon Combination Screwdriver is a versatile tool that is perfect for a variety of tasks. Its strong permanent magnet ensures that bits are held securely in place, while its 120mm blade length makes it ideal for reaching tight spaces. Additionally, its 1/4″ head size makes it perfect for use with a variety of different bits.

How much does it cost to calibrate a torque screwdriver

There are a few different variables that will affect the cost of calibration for a wrench. The first is the capacity of the wrench. Typically, the higher the capacity, the greater the cost of calibration. The second variable is the frequency with which the wrench is used. If the wrench is used regularly, it will require more frequent calibration than if it is used less often. The third variable is the accuracy required for the calibration. If the calibration needs to be extremely accurate, it will be more expensive than if it only needs to be moderately accurate. Finally, the location of the calibration will also affect the cost. If the calibration needs to be done at a specialized facility, it will be more expensive than if it can be done at a local repair shop.

And the fix for that is really easy – all you have to do is turn it on and leave it for a few minutes. So when you turn it on, just leave it for a few minutes and it should fix the problem.

How do you adjust the torque on an electric drill?

The collar numbers on a screwdriver refer to the amount of torque that the screwdriver can deliver. The higher the number, the higher the torque. To adjust the torque, align the arrow on the collar to the desired setting.

If you are working on a car, it is important to know the torque specs for the axle nut (and other nuts and bolts). The dealership or shop that you purchased the car from should have a guide that lists the torque specs. If you can’t find that information, you can look in the service manual for the car.

How do you adjust torque extensions

Most torque wrenches have a mark on the handle that indicates the center of the wrench. The handle is typically longer on one side of the center than the other. This side is usually the side that you use to apply more torque.

If the torque is too high, the wheels might spin, or the axle might break. This is because the force required to rotate the wheel is too great for the wheel or axle to handle.

Conclusion

There is no one definitive answer to this question, as the process for adjusting a Wera torque screwdriver may vary slightly depending on the specific model. However, in general, the process involves loosening the set screw on the torque screwdriver, adjusting the torque setting to the desired level, and then re-tightening the set screw. For more detailed instructions, it is advisable to consult the manual for your particular model of Wera torque screwdriver.

If you need to adjust the torque on your Wera torque screwdriver, you can do so by turning the adjustment knob on the back of the tool.