A metal try square is an essential tool for any machinist or woodworker. It is used to test the accuracy of 90 degree angles. Making your own metal try square is a relatively simple process that can be done with a few tools and a little bit of know-how. In this article, we will show you how to make a metal try square that is both accurate and durable.

Using a Try Square

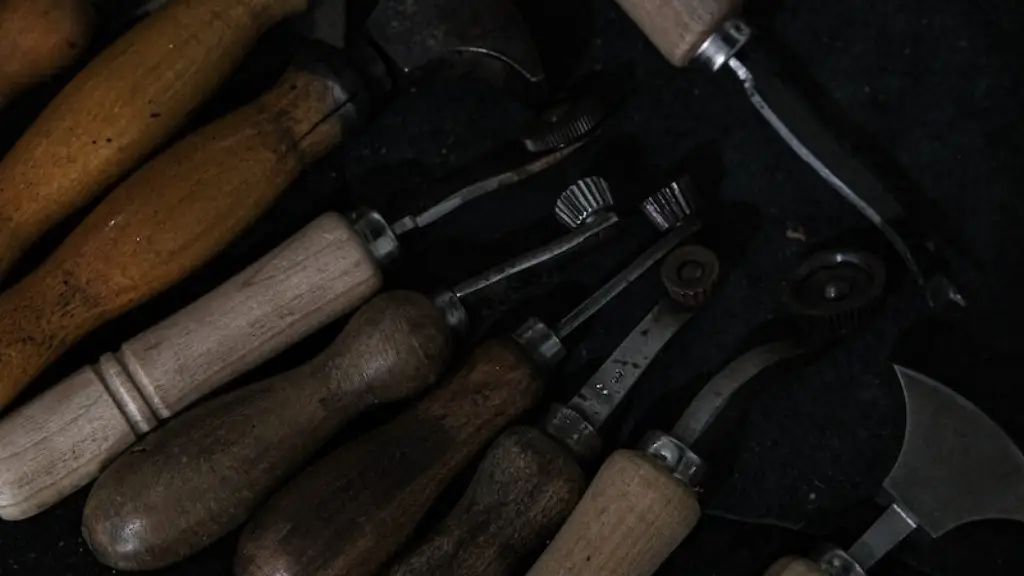

A try square is one of the most useful tools in the shop, and is used for a variety of tasks, from checking the 90º angle of a machined surface to scribing a line on a workpiece. There are a number of different types of try squares available, but the most common is the metal try square.

To use a try square, first make sure that the blade is perpendicular to the handle. The blade should be at a 90º angle to the handle. Next, place the try square against the surface you want to check for squareness. The blade should be flush with the surface, with the handle extended away from the surface. If the surface is square, the blade will be flush with the surface. If the surface is not square, the blade will not be flush with the surface.

How do you make a try square?

This is a great project for anyone who wants to try their hand at woodworking. The first step is to cut the post to the desired length. The next step is to cut the mortise. This is done by using a mortising gauge to lay out the thickness of the mortise. Once the mortise is cut, the next step is to cut the beam to shape. After the beam is cut, the next step is to glue it into the post. The final step is to adjust the square and finish it.

There are many factors that can affect the angle of a metal line. If the angle is less than 90 degrees, then you should strike the square on the inside corner of the line. This will cause the metal to bend more easily. If the angle is more than 90 degrees, then you should strike the square on the outside corner of the line. This will cause the metal to break more easily.

What is the metal work version of a try square called

A machinist square or engineer’s square is the metalworkers’ equivalent of a try square. It consists of a steel blade inserted and either welded or pinned into a heavier body at an angle of 90°. Usually a small notch is present at the inside corner of the square.

This is a method for checking whether a surface is square. First, measure three units across from one corner, and make a mark. Then, measure four units up from the same corner, and make a mark. Finally, measure the distance between the two marks. If the distance is five units, the surface is square. If the distance is more than five units, the surface is more than 90 degrees.

What angle is a try square made at?

A try square is a handy tool used to check if the edges and faces of a piece of wood are straight, flat, and square to one another. The square in the name refers to the 90° angle. To try a piece of wood is to check if it is the correct size and shape. A try square is so called because it is used to try how square the workpiece is.

These lines are used to help people make more accurate marks. The smaller the mark you make, the more accurate it will be.

How do you square a piece of steel?

You can usually get it pretty right by hooking that just make sure you hook at the same on both sides of the zipper. Also, if you’re using a skirt or pants with a zipper, make sure the teeth are facing the right way or you’ll be zipping up your fly all day.

To get a perfectly square corner, you want to aim for a measurement ratio of 3:4:5. In other words, you want a three-foot length on your straight line, a four-foot length on your perpendicular line, and a five-foot length across. If all three measurements are correct, you’ll have a perfectly square corner.

How do you use a steel square step by step

Step 1 hold the framing square in your hands Note that it is made of one flat sheet of metal with two L-shaped arms that are hinged together at one end You will use the framing square to measure both short and long distances

Step 2 open the arms of the framing square so that the distance between them is about 2 feet longer than the width of the object you are measuring

Step 3 place the framing square against one end of the object with the L-shaped arms flush against the sides of the object

Step 4 mark the distance from the end of the object to the end of the long arm of the framing square with a pencil

Step 5 move the framing square to the other end of the object and mark the distance from the end of the object to the end of the long arm of the framing square again

Step 6 measure the distance between the two marks with a tape measure to get the length of the object

Machinists squares are typically made entirely from hardened tool steel. This makes them extremely durable and resistant to wear. On the other hand, try squares are often made using a wooden handle (the stock), with a metal blade pinned or riveted to it at precisely 90°. This construction makes try squares lighter and easier to handle, but they are not as durable as machinists squares.

What connects the blade and stock of a try square?

A traditional carpenter’s try square is a measuring and marking tool composed of a blade of tempered steel fixed at a 90-degree angle to a wooden stock. The blade is secured to the stock with rivets that pass through brass plates on each side of the stock. This type of square is used by carpenters and woodworkers to mark and measure cuts on lumber.

The try square has a stock and a blade set at a right angle to each other. The stock has a metric scale on one side and an imperial scale on the other. The mitre square is the same as a trysquare, but the blade is set on the stock at a 45 degree angle.

What can I use instead of a square

There are many different options to consider when it comes to payment processing, and Square is just one of many options. Some other popular options include Stripe, Toast, Lightspeed, Shopkeep, Shopify, Revel, and PayPal Here. Each of these options has its own set of features and benefits, so be sure to do your research to find the best fit for your business.

If you’re looking for an alternative to Square, there are a few options out there. PayPal Zettle, SumUp, and Shopify are all great options that offer similar services. Each has its own unique features and benefits, so be sure to check out each one to see which one is right for you. Keep in mind that some of the products featured on this page may be from our partners, which means we may receive compensation if you decide to sign up for one of their services.

What is the 3 4 5 triangle method?

If you’re looking for a quick and easy way to check if an angle is 90 degrees, the 3:4:5 triangle rule is a great method to use. Simply measure the length of one side of the triangle, and then measure the length of the adjacent side. If the diagonal between those two points measures 5, then you can be certain that the angle is 90 degrees.

This 4-piece try square set is perfect for any engineer. The set includes squares with overall sizes of 50mm, 75mm, 100mm, and 150mm. The blades are made of high-quality steel and are 17mm thick.

How do you cut angles to make a square

When cutting baseboard trim, it is important to line it up in the center of the saw. This will help ensure that the trim is cut evenly. Be sure to lower the blade slowly and carefully to avoid any mishaps.

The SpecificationsAttribute is a value assigned to a blade that denotes its length, width, and thickness. The most common attribute value is 4 inches, however, some blades may have values of 3 or 6 inches. The thickness of the blade is usually16mm, but may be different for certain types of blades. The width of the blade is also typically 188 mm, but this may vary depending on the make and model of the blade.

Final Words

Use a hammer and an anvil, or a bench vise, to flatten one end of a piece of flat stock steel.

Measure and mark the stock at the desired Try Square length.

Use a hacksaw to cut the stock along the marked line.

Next, use a file to clean up the cut edge.

Use a hammer and an anvil, or a bench vise, to curl the end of the steel stock that was just cut.

Bend the steel until the curled end meets the flat surface of the stock.

Mark and cut the steel at the point where the curl meets the stock.

Use a hammer and an anvil, or a bench vise, to flatten the curled end of the steel stock.

Your Try Square is now complete.

A metal try square can be used to make accurate markings on wood and other materials. It is a handy tool for any woodworker or hobbyist. To make a metal try square, you will need a piece of metal stock, a file, and a hammer. First, cut the metal stock to the desired size. Then, file the edges of the metal stock to create a smooth, finished surface. Finally, use a hammer to punch a hole in the center of the metal stock. This hole will be used to attach the metal try square to a workbench or other surface.