Welding pliers are used to grip and manipulate metal objects during the welding process. They are specifically designed to withstand the high temperatures and forces involved in welding. There are several different types of welding pliers available, each designed for a specific purpose. Knowing which type of welding plier to use for each task is essential to getting the best results.

1. Before using welding pliers, always check that the jaws are clean and free of debris.

2. Open the jaws of the pliers and hold them close to the welding torch.

3. When the torch is turned on, the welding pliers will become hot.

4. Use the welding pliers to grip the welding wire and guide it into the weld pool.

Why do you need welding pliers?

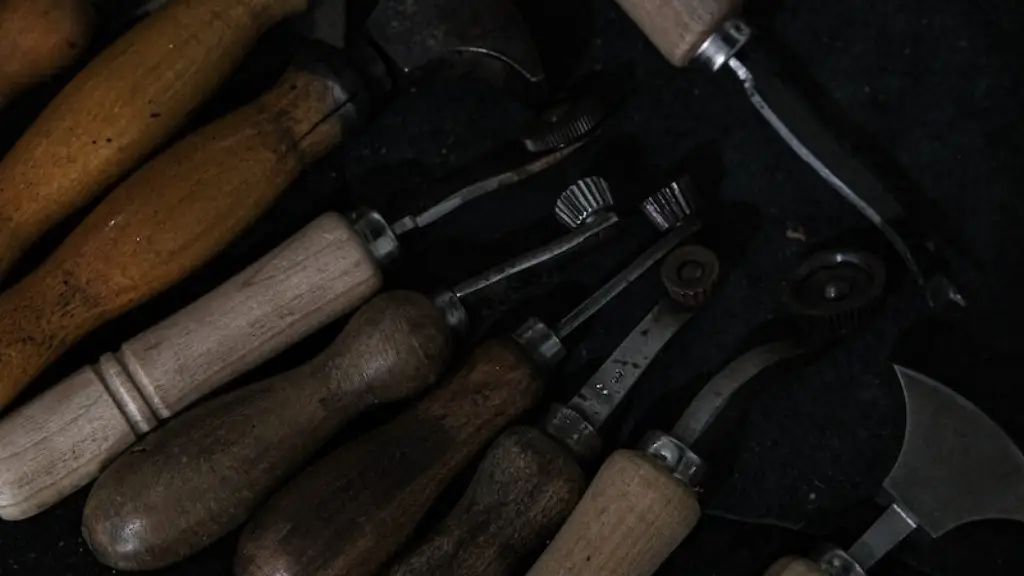

Welding pliers are a single tool designed for six functions which include nozzle and tip installation, wire cutting, nozzle cleaning, slag hammer and spatter removal. The welding pliers are drop forged steel constructed and come with a form fitting handle.

The clamp is used to hold the panels tight around the area to be welded and the copper backer acts as a heat sink to dissipate heat away from the area to be welded. This prevents the panels from warping or melting during the welding process.

What does a MIG pliers do

If you’re going to be MIG welding, you’re going to want a good pair of pliers. Reliable MIG welding pliers will allow you to remove the nozzle, loosen the contact tip, remove weld spatter and cut wire with ease. Bad quality pliers will leave you frustrated having to replace them each time.

It is important to avoid abuse and misuse of these pliers in order to prevent damage. Exposing them to excessive heat, for example, can damage the tool. Bending stiff wire with the tip of the pliers can also cause damage, as can rocking the pliers side to side when cutting. Finally, prying with the nose of the pliers can damage the tool and is not recommended.

What are 2 things that welding pliers would be used for?

Welding pliers are a versatile tool that can be used for a variety of tasks, from removing weld spatter to hammering away at slag. They can also be used in MIG welding to remove and install the tip, as well as draw out the wire and cut it.

When you rub your hands together, you create friction which generates heat. The faster you rub your hands together, the more heat is generated.

How do you spot weld with a MIG?

To set up your MIG welder with the kit, all you have to do is unscrew the nozzle and screw on the spot weld nozzle. It’s that simple! Start by lining up the two panels to be welded, and make a mark where you want them to sit as well as where you want the weld to be.

A spot weld is a type of weld that is typically used to join two pieces of metal together. In order to create a spot weld, an electrical current is used to heat up the metal, which causes the metal to melt and fuse together. When spot welding, it is important to ensure that there is a sufficient overlap of the individual sheets being welded, as this is necessary in order to obtain adequate joint strength. Additionally, it is recommended that the distance between two spot welds should be a minimum of 10 times the material thickness.

Do you push or pull with MIG

There are a few key factors that contribute to weld strength. First, the angle of your weld bead is important. For instance, welding instructors will tell you that MIG welding with flux core on aluminum will always require a push angle. However, once you switch to another material, such as steel, you may need to consider pulling your weld bead instead.

Another important factor is joint design. The type of joint you’re welding will dictate how strong your weld will be. For example, a butt joint is stronger than a lap joint.

Finally, the type of metal you’re welding also plays a role in weld strength. Softer metals, like aluminum, are more difficult to weld than harder metals, like steel.

Pushing usually produces lower penetration and a wider, flatter bead because the arc force is directed away from the weld puddle. In addition, pushing usually offers a better view and enables you to better direct wire into the joint.

Is it better to drag or push MIG welding?

While pulling might create a deeper penetration, in most situations, pushing creates a flatter weld that covers more surface area. In some instances, this can create a stronger weld than what you might get with the pull technique. As mentioned, pulling allows you to watch your bead as it’s being produced.

When cutting wire with diagonal cutters, nip off small pieces at a time, rather than cutting through the wire in one stroke.

Cutters are not for prying! Use a separate tool, such as a screwdriver, for prying apart objects.

Keep cutters clean and free of dirt and grit, which can dull the cutting edges.

What is one thing pliers should never be used for

Pliers are a great tool for gripping and cutting, but they should never be used for loosening or tightening nuts and bolts. That’s a job for a wrench.

When using pliers, always be sure to protect your eyes from flying debris. Only use pliers for their intended purpose and never force them to do a job they’re not meant for. Be sure to use the correct type of pliers for the job at hand to avoid damage to the materials you’re working with. Finally, don’t expose your pliers to excessive heat as this can damage the tool.

What are the five 5 welding essentials?

Welding is a process of joining two pieces of metal together by heating the metal until it melts and then cooling it so that it forms a permanent bond. There are several factors that need to be considered in order for a welding procedure to be successful.

The first factor is the size of the electrode. The electrode needs to be the correct size for the metal being welded. If it is too small, the electrode will not be able to conduct enough current to melt the metal. If it is too big, the electrode will conduct too much current and the metal will melt too quickly.

The second factor is the current. The welding current needs to be strong enough to melt the metal, but not so strong that it causes the metal to vaporize.

The third factor is the arc length or voltage. The arc length is the distance between the electrode and the metal being welded. The voltage is the amount of electrical potential difference between the electrode and the metal. Both the arc length and voltage need to be correct in order for the weld to be successful.

The fourth factor is the travel speed. The travel speed is the speed at which the electrode is moved along the metal. If the travel speed is too slow, the metal will

When it comes to welding, safety should always be your top priority. Before you even begin welding, you should make sure that you have the proper safety equipment. This includes safety glasses, welding gloves, an auto-darkening helmet, and a fire-resistant jacket. By taking these precautions, you can help ensure that you have a safe and successful welding experience.

What are the 2 basic tools required by a welder

There are a few different types of welding tools that are good for beginners. A welding helmet is a must-have for safety, and gloves are also a good idea. Welding magnets are very versatile and can be used for a variety of tasks.

Welding in the same spot twice can create a conductive path that can cause electrical issues. It is best to avoid welding in the same spot twice to prevent any potential problems.

Warp Up

Use welding pliers to grip and hold hot metals.

Welding pliers are an important tool for any welder. They are used to hold the welding rod in place while welding. They also help to keep the welding area clean and free of debris. Welding pliers come in a variety of sizes and shapes, so it is important to choose the right size and style for the job.