If your electric drill has stopped working, don’t despair! With a little time and effort, you should be able to fix it. This guide will walk you through the process of repairing an electric drill.

To repair an electric drill, first troubleshoot the problem to see if it is a simple fix. If the drill will not turn on, check the power cord and ensure that it is plugged into a working outlet. If the drill does not have enough power or torque, check the brushes and clean them if necessary. If the drill is still not working properly, take it to a qualified repair person.

Can electric drills be repaired?

It’s important to know when to repair or replace your tools. There are times when repairs can cost as much as a new drill, but often a little maintenance and a few inexpensive parts may be enough to restore the tool. There are a few repairs, like replacing gears, bearings or motor parts, that should be left to professionals.

There are a few possible reasons for a defective power drill claim. One reason could be lack of proper safety guards. Another reason could be improper warning provided. A third reason could be manufacturing flaws. A fourth reason could be inadequate quality inspection.

How do you fix a drill that won’t spin

If your drill is spinning off-center, the most likely cause is that the drill bit is not properly centered in the chuck. Be sure to check that the drill bit is fully inserted into the center of the chuck, and is not clamped off-center. With the drill bit properly centered, your drill should spin straight.

There is no one definitive answer to this question, as it depends on the specific model of Rawls screwdriver (or other tool) in question. However, in general, it is common for Rawls screws to have the screws located on the side of the tool, which allows for easy access and opening of the case.

What makes a drill stop working?

If your drill stalls, it’s likely because it’s overloaded or being used improperly. Immediately release the trigger, remove the drill bit from the work, and determine the cause of the stall. Don’t press the trigger on and off in an attempt to start a stalled drill—this can damage the drill.

If you notice your handheld electric drill slowing down or not working as well as it used to, it might be because of dirt, dust, or grime build-up on the copper connections of the armature. To clean them, simply remove the drill bit and brush away the debris with a soft brush.

What are the common drilling problems?

The most prevalent drilling problems include:

Pipe sticking: This occurs when the drill pipe becomes stuck in the borehole. This can happen due to a number of reasons, including:

Loss of circulation: This occurs when the fluid being used to lubricate and cool the drill bit is lost. This can happen due to a number of reasons, including:

Hole deviation: This occurs when the borehole starts to deviate from the vertical. This can happen due to a number of reasons, including:

Pipe failures: This can happen due to a number of reasons, including:

Borehole instability: This can happen due to a number of reasons, including:

Mud contamination: This can happen when the mud used to lubricate and cool the drill bit becomes contaminated. This can happen due to a number of reasons, including:

Formation damage: This can happen when the rocks and minerals in the formation are damaged. This can happen due to a number of reasons, including:

Hole cleaning: This is the process of removing the drill cuttings from the borehole. This can happen due to a number of reasons, including:

If your drill keeps tripping the circuit breaker, it is likely due to an overloaded circuit, short circuit, or ground fault. To fix the problem, you may need to use a different circuit or unplug an item on the current circuit.

What are the common problems of electric power tools

The most common power tool performance problems are:

1. Functions at low power levels – this means that the tool is not getting enough power to function properly.

2. Emits high-pitched noises – this is usually an indication that the tool is overloaded and about to fail.

3. Sets off sparks and smoke – this means that the tool is overheating and is in danger of catching fire.

4. Releases a burning smell – this means that the tool is burning up and is in danger of exploding.

5. Doesn’t power on or start – this means that the tool is not getting any power at all and is useless.

The reason your screw won’t go into the wood is that it has reached a dense section of wood and needs more force. To mitigate the issue, you can drill a larger pilot hole or use a better quality screw. You may also need a more powerful drill/driver.

How do you unfreeze a drill?

A bench vise is a great way to hold your workpiece while drilling. By holding the workpiece in the vise, you can keep your hands free to operate the drill. Plus, the vise will help to keep the workpiece from moving or slipping while you’re drilling.

There is a noise that you can hear right now that is resetting itself. You can go back to it if you want.

What are the parts of an electric drill

While the term “drill press” most commonly refers to a floor-mounted tool, there are also drill presses available in a benchtop or portable form. The major components of a drill press include a base, column (or pillar), adjustable table, spindle, chuck, and drill head, usually driven by an electric motor. The head typically has a set of three handles radiating from a central hub that are turned to move the spindle and chuck vertically.

We guarantee to repair any defects in materials or workmanship free of charge. For warranty repair information, please call 1-800-4-DEWALT (1-800-433-9258) or fill out the form at https://supportdewalt.com/hc/en-us/requests/new.

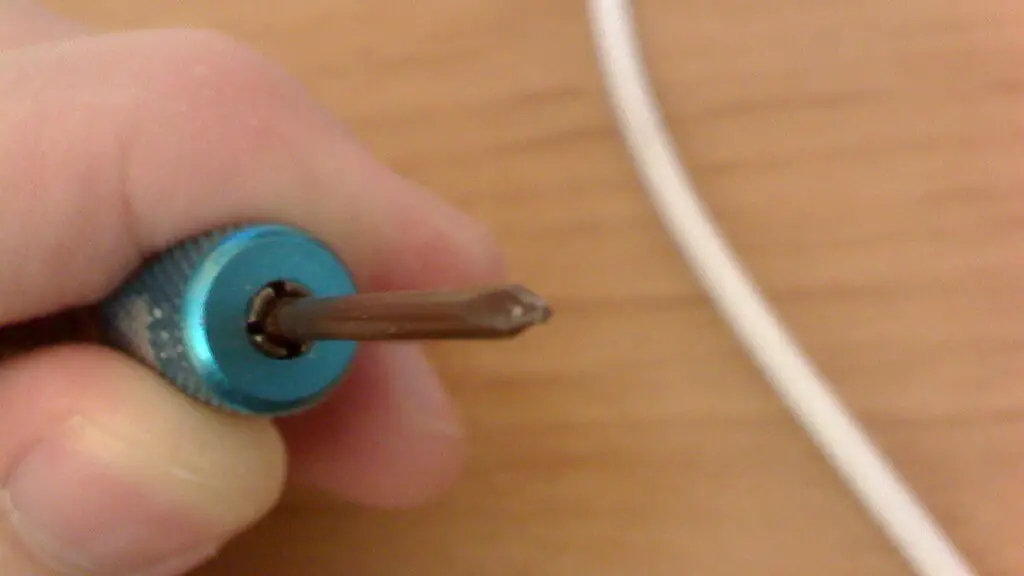

Can you take a drill chuck apart?

Always be careful when working with tools. If a screw is present, be sure to remove it before proceeding. These retaining screws always have a left hand thread, so be sure to turn clockwise to remove it.

The average lifespan of a Lithium-ion cordless drill battery is best stated in charging cycles instead of time, and the typical range is 1,000 to 1,200 cycles. That means a pro charging multiple times every day is going to get 3 to 5 years out of a battery before it needs replacing.

How do you test a drill motor

This is how you connect a battery to a motor. First, you grab a couple leads and hook them up to the battery. Then, you hook one lead to the lead on the motor.

While a cordless drill may not last you an entire lifetime, it will last until the battery pack dies and you can no longer find compatible replacement batteries. For this reason, it may be a good idea to invest in a good quality corded drill and a few extension cords. This way, you can be sure that your drill will last for many years to come.

Final Words

If your electric drill is not working properly, there are a few things you can do to try to fix it. First, check the power cord to make sure it is not frayed or damaged in any way. Next, check the switch to see if it is turned on. If the drill is still not working, you may need to replace the chuck.

To repair your electric drill, you will need to first identify the problem. Once you know what is wrong, you can either fix it yourself or take it to a professional. If you take it to a professional, make sure to get a estimate first. With a little bit of knowledge and some effort, you can easily repair your electric drill.