In this article, we will discuss how to make a screwdriver handle. The screwdriver handle is a very important part of the screwdriver, and it is important to choose the right handle for your needs. There are many different types of screwdriver handles, and each has its own advantages and disadvantages. We will discuss the different types of handles and how to choose the right one for your needs.

There is no one-size-fits-all answer to this question, as the best way to make a screwdriver handle will vary depending on the specific project you are working on. However, some tips on how to make a screwdriver handle include using a sturdy material such as wood or metal, and making sure that the handle is a comfortable size for your hand. You may also want to consider adding a grip or nonslip surface to the handle to make it easier to hold.

How do you make a screwdriver handle at home?

We just need the metal part of the handle to be replaced. I took an old craftsman knife and removed the handle. I then took the new handle and placed it over the metal part of the knife. I used a small Phillips head screwdriver to tighten the screws.

Cellulose acetate is a type of plastic that is commonly used to make the handles of screwdrivers. The material is delivered to factories in powder form and is mixed with a liquid plasticizer in a large blender. The resulting mixture is then used to create the handles of the screwdrivers.

How do you make a screwdriver grip

If your screw is stripped or worn out, putting a wide rubber band between your screwdriver and the screw head can give you a better grip.

S2 tool steel is an excellent impact-resistant steel that is used to make high-hardness Allen wrenches, screwdrivers, etc. Tools made of this steel have a sufficiently high hardness after heat treatment.

What plastic are screwdriver handles made of?

Cellulose acetate butyrate is a clear plastic screwdriver handle material developed in the 1930s. Its primary component, cellulose acetate, is made by reacting cellulose from wood pulp with a variety of acids.

The electricians use tools like screwdrivers and pliers for repair work and the handles of these tools usually have plastic or rubber covers on them. This is done to protect the electrician from getting electric shocks.

Why do screwdriver handles have ridges?

The purpose of the flats or irregularities on a screwdriver handle is to improve grip and prevent the tool from rolling. This is especially important when working on a flat surface, as it can be difficult to keep the screwdriver in place otherwise. Having a good grip on the screwdriver is also important for safety, as it can help to prevent accidental slips or drops.

This CRAFTSMAN screwdriver set is a great addition to any toolkit. The set includes 42 pieces, each with an acetate handle and a satin-nickle finish. The screwdrivers are made of steel for durability, and the set comes with a carrying case for easy storage and transport.

Why do old Craftsman screwdriver handles smell

The problem with old tool handles is that they start releasing butyric acid and free acetic acid. Butyric acid, in particular, smells like smelly socks. It’s a carboxylic acid, and the bad part is that it migrates within your confined toolbox, which means other tools absorb some of that nasty stink.

If you’re having trouble getting a manual screwdriver to work, you can try covering the screw with a rubber band or duct tape to give it extra grip.

How do you make a screwdriver insulated?

You can apply painters tape to the tip of the nail if you want to create a clean, straight line. Simply remove the tape while the polish is still wet for a perfect result.

When choosing a contoured handle, make sure that it fits the shank tightly and has a flange to keep your hand from slipping off the tool. This will help you maintain a firm grip on the tool, making it easier to control.

Are all screwdriver handles insulated

It is important to use insulated tools when working with high voltages, as regular tools may not provide sufficient insulation to protect the user from electrical shock. High voltage can travel along the steel core of the tool and quickly make the jump to the user through that thin plastic handle, so it is important to use insulated tools to avoid potential injury.

This is an important safety feature of these tools, and it’s something to be aware of if you’re ever working with them.

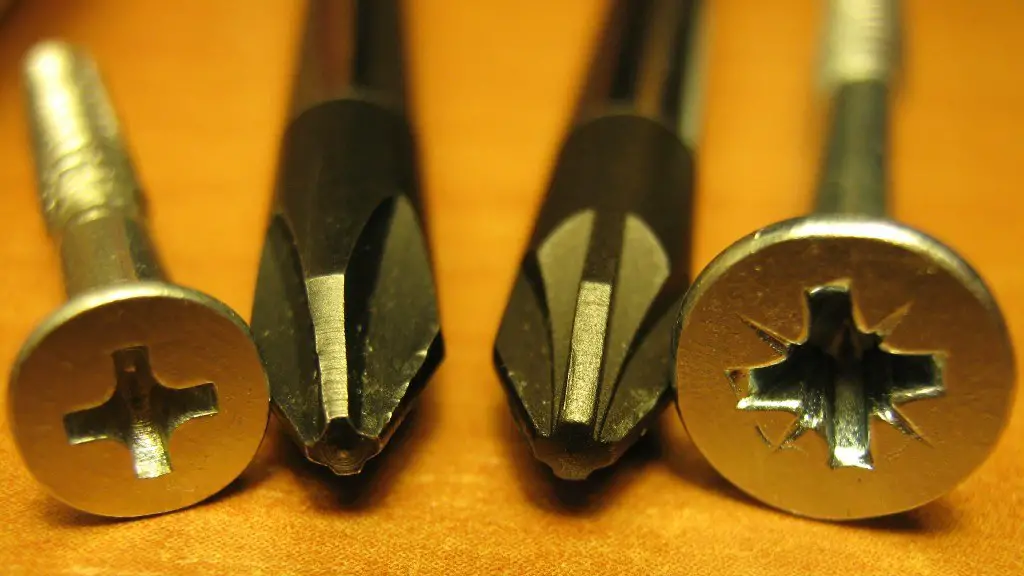

What is the best metal for screwdriver?

Cr-V steel is the most popular steel used for screwdriver bits. It is known for its hardness (around HRC52 ±2) and its torque value (around 180~190 kgf·cm).

Plastisol is a type of PVC that is combined with plasticizers to add stretchiness and flexibility. When heated, it forms a liquid that can be used to coat tools. The temperature of the tool determines how thick the coating will be.

What plastic is used to make handles

Bakelite is a thermosetting plastic that is a poor conductor of heat. It is used to make the handles of utensils so that the person holding the hot utensil doesn’t get burnt.

Injection molding is a popular manufacturing method for mass production of plastic parts. It is versatile and molds can be designed as per the client’s requirements. Plastic is melted and poured into a mold and then allowed to cool to get the desired shape and size.

Final Words

To make a screwdriver handle, you will need a piece of wood that is 3/4 inch thick and 4 inches wide. Cut the piece of wood to the desired length and then drill a hole in the center of it. Next, take a file and make a V-shaped notch in the top of the wood. Finally, use a router to make a groove around the edge of the wood.

There are many ways to make screwdriver handles, but the most common is to use a piece of wood. Cut a piece of wood to the desired shape and size, then drill a hole in the center. Next, insert the screwdriver shaft into the hole and glue it in place. Finally, sand the handle and apply a finish of your choice. This is a quick and easy way to make a screwdriver handle that will last for many years.