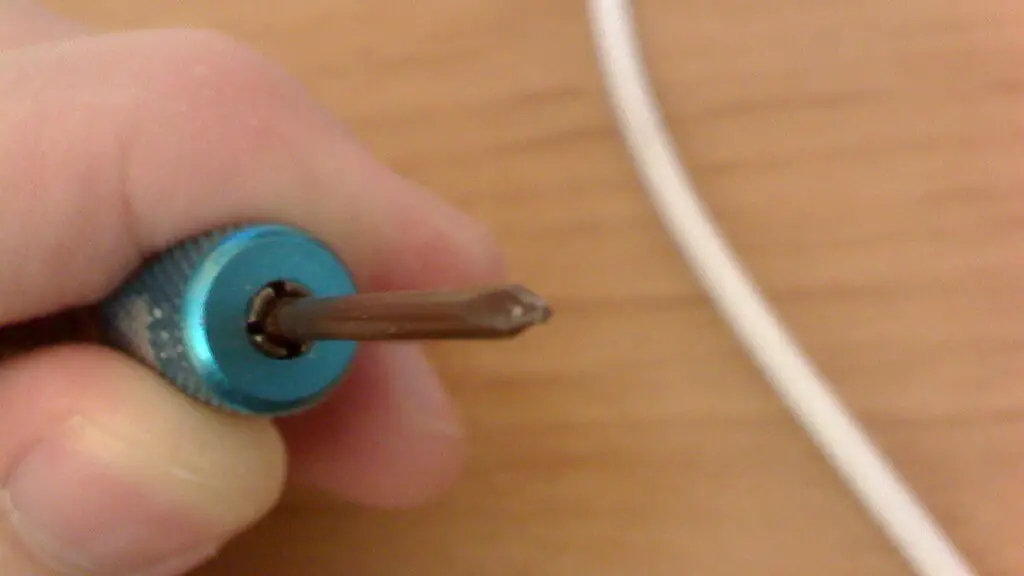

A soldering iron is a device that applies heat to a workpiece in order to melt solder and join two pieces of metal together. A screwdriver can be used to make a simple, quick, and easy soldering iron. This method is ideal for those who do not have access to a soldering iron or for those who need a soldering iron in a pinch.

Use a screwdriver to remove the tip of the soldering iron. Next, use a file to remove any burrs from the tip. Next, use a soldering iron stand to hold the tip in place. Next, use a soldering iron to heat the tip for a few seconds. Finally, use a screwdriver to screw the tip back on.

What can I use instead of a soldering iron?

If you’re trying to solder something, you’ll need to heat the metal up to the melting point of the solder. This can be done with a butane lighter, candle, oil lamp, alcohol burner, or even an open campfire. Just make sure that whatever you’re using is able to get the metal hot enough to melt the solder.

Now go ahead and put the wire Into the Chuck of the drill And then I want to be able to try to get the wire as tight as possible. After that, you can go ahead and put the drill on the highest setting and start drilling through the wood.

How to make a 12 volt soldering iron at home

Now connect LED and 1k resistor with positive and negative wire now connect push-button between positive and ground wire.

Now to tin the soldering iron tip you just melt solder directly onto the hot iron tip. But this is not the correct way to do it. You should actually apply the solder to the joint first, then touch the tip of the soldering iron to the solder. This will cause the solder to flow up the iron tip and coat it.

Can you solder with a paperclip?

We need some pliers so that we can cut paper clips. You can’t cut paper clips without them, so make sure to get a good pair!

Vaseline is a great alternative to commercial flux and works just as well. It is made from waxes and mineral oils so it won’t corrode your components and it also cleans away the gunk and eliminates metal oxides that could compromise your bond.

What metal is best for soldering iron tip?

Copper is better than iron for many reasons, one of which is that it has acceptable transfer properties. This means that heat can be transferred more easily from one area to another, making it ideal for soldering.

A screwdriver tip helps deliver heat to solder joints greater than 40 mm W on PCBs and can also be used for general soldering tasks. The tip is made of a material that is a good conductor of heat and is able to transfer heat quickly to the solder joint. The tip is also able to hold onto the heat for a short period of time, which is helpful when working with large solder joints.

Is copper tip good for soldering

Copper is a great choice for transferring heat quickly and evenly. It’s ability to exchange heat between itself and the piece being soldered makes it ideal for the job.

You should never solder directly on a battery. It might not be dangerous, but you will hurt the cell. If you must solder, do it where I have marked in red, and squeeze a fishpaper or something that can take the heat away from the cells. The best solution is to spot weld a new nickel-plated steel tab and than solder.

What is the number 1 rule of soldering?

When soldering, it is important to make sure that the area which you wish to solder is clean, dry and free from grease. This will ensure that the solder adheres properly and creates a strong connection.

This is a simple way to create a strong electrical connection between two wires. It is often used in electrical repairs and installations.

What is the easiest metal to solder

Different metals have different properties that make them more or less difficult to solder to. For example, copper and tin are both relatively soft metals that are easy to work with, while brass and steel are harder and more difficult to solder to. In general, the softer the metal, the easier it is to solder to.

Solder is a metal alloy that is used to create a strong electrical bond between two materials. It is typically made of tin and lead, and is melted using a hot iron. The iron is heated to temperatures above 600 degrees Fahrenheit, which then cools to create the solder joint.

Is soldering just mini welding?

Welding involves using a high heat source to melt the workpieces, which are then joined together. Soldering, on the other hand, uses a low heat source to melt the filler metal, which is then used to join the workpieces together.

This is obviously a very frustrating situation to be in. It can be difficult to keep trying when it seems like nothing is working. However, it is important to continue to persevere and find ways to improve. There are a few things that you can do to increase the chances of success:

1. Make sure that you are using the right method. There are a lot of different methods out there and it is important to find the one that is right for you.

2. Be patient. Learning something new can take time and it is important to be patient.

3. Practice. Repetition is key when it comes to learning something new. The more you practice, the better you will become.

4. Get help. If you are struggling, don’t hesitate to seek out help from a friend, teacher, or tutor.

5. Stay positive. Learning can be frustrating, but it is important to stay positive and believe in yourself.

Is there a glue that works like solder

MesoGlue is a room-temperature metallic glue that lets you stick parts together with reckless abandon and electrical control. This could be really useful for soldering or welding, as it would prevent things from getting too hot.

Solder is metal, and is used to make a connection between components in an electronic circuit. Super glue is a cyanoacrylate, which does not conduct electricity.

Final Words

To make a soldering iron with a screwdriver, you’ll need a few things: a screwdriver, a power drill, a drill bit, some heavy-duty wire, and a soldering iron. First, find a screwdriver that fits snugly into the power drill. Next, use the drill bit to make a hole in the screwdriver’s handle. Then, thread the heavy-duty wire through the hole and around the screwdriver’s tip. Finally, use the soldering iron to heat up the wire until it’s hot enough to melt solder.

If you want to know how to make a soldering iron with a screwdriver, then you’ve come to the right place. This guide will teach you everything you need to know in order to get the job done right. First, you’ll need to gather the following supplies: a screwdriver, a soldering iron, a piece of copper wire, and some solder. Next, you’ll need to follow these simple steps:

1. Strip the insulation off of the end of the copper wire.

2. Wrap the wire around the shaft of the screwdriver.

3. snug the wire up against the soldering iron.

4. apply solder to the connection between the wire and the soldering iron.

5. allow the solder to cool and solidify.

6. Test the new soldering iron by using it to solder two pieces of scrap metal together.

There you have it! Now you know how to make a soldering iron with a screwdriver.