A torque screwdriver is a specialized tool that is used to apply a specific amount of torque to a screw or bolt. It is used to ensure that the screw or bolt is tightened to the proper level, which can help prevent damage to the object being tightened. There are many different types of torque screwdrivers, and the best one for a particular job will depend on the specific requirements of that job.

The best torque screwdriver for the job is the one that will torque the screws to the correct level and not strip the heads.

What is a good torque for a screwdriver?

Electric torque screwdrivers are used for light assembly applications, such as electronic and small parts assembly. The range of torque in one of these tools is typically between 017 In Lb to 870 In Lb, with speeds in excess of 2000 RPM. This makes them ideal for use in applications where a high degree of accuracy is required.

A torque screwdriver is a tool that is used to apply a specific amount of torque to a screw, nut or other fastener. This is done by using a torque-limiting clutch that disengages when the desired torque is reached, preventing the screw from being over-tightened. Torque screwdrivers are used in many industries, such as automotive, aerospace and manufacturing, where it is critical to follow precise assembly instructions.

What is the advantage of using a torque screwdriver

An adjustable torque screwdriver is a great tool to have for any repair project. Not only does it make it easier to use than a manual screwdriver, but it also offers more precision and control when tightening or loosening screws. Additionally, an adjustable torque screwdriver can help to improve the overall accuracy of your repairs, saving you time and money in the long run.

It’s important to keep your torque tools in good working condition, as they are precision instruments used for critical, often safety-sensitive tasks. Hand tools in particular can go out of calibration with use, so it’s important to test and calibrate them frequently to maintain consistent tool performance and accuracy.

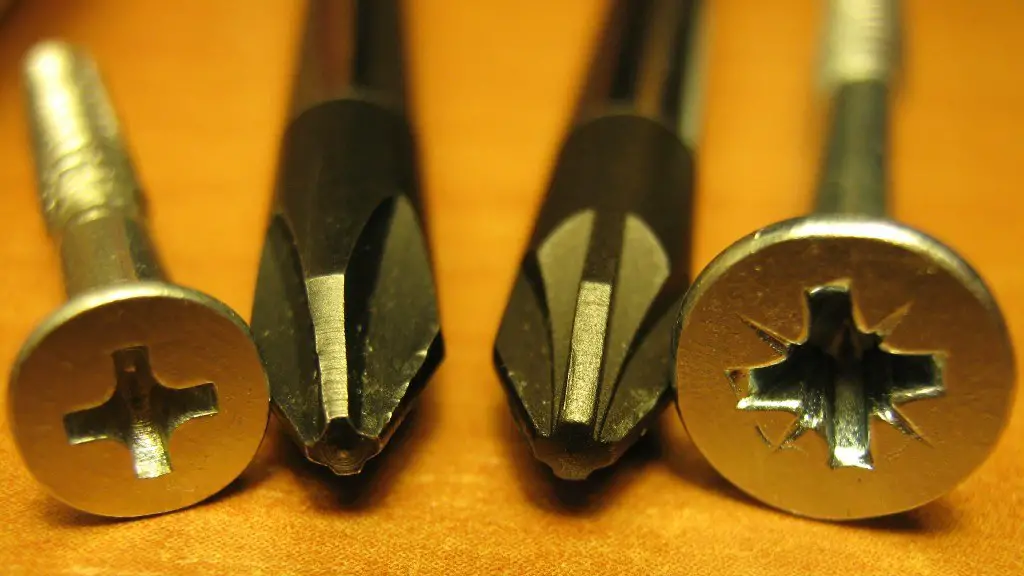

What screw head has the most torque?

There are a few different types of screw heads that are typically considered to be the strongest. These include star-shaped Torx bits, square-shaped Roberts bits, and well-fitted Philips head screws. However, it is important to keep in mind that the type of screw head is not the only factor that determines the strength of the screw. The materials used to make the screw and the fit of the drill bit are also important considerations.

If you need a drill driver that can provide a lot of torque, you should consider getting one that runs on 72 volts. The suggested battery capacity for this type of drill driver is 15 Ah. Keep in mind that a professional drill driver is usually more suited to your demands if you need a lot of torque.

How accurate is torque screwdriver?

Torque measurement is an important quality control check in many industries, such as automotive and aerospace. A torque screwdriver is a precision tool that allows manufacturers to ensure that their products meet the required torque specifications. The ISO 6789 standard specifies that a torque tester must be accurate to +/- 15% of the full-scale value in order to properly measure torque from a torque screwdriver. This means that a torque screwdriver with a +/- 6% tolerance is within the acceptable range for testing.

A torque wrench is a vital tool for anyone who needs to work with fasteners. It allows you to apply a specific level of torque to a bolt or nut, which is essential for ensuring safety in many industries. Torque wrenches come in a variety of sizes and styles, so you can find the perfect one for your needs.

Does longer screwdriver increase torque

Although it may seem odd, the different lengths of screwdrivers don’t really affect torque directly. Torque is the force applied multiplied by the distance from the axis you are rotating about. So the torque of the screwdriver only really depends on the thickness of the handle.

The average human hand is quite strong and can apply 100N of force easily. This is a good thing to know if you ever need to apply force to an object or if you’re ever in a situation where you need to resistant force.

What are the three most commonly used torque wrenches?

A torque wrench is a tool that is used to apply a specific amount of torque to a fastener, such as a nut or bolt. Torque wrenches come in a variety of sizes, with the most common being ¼-, ⅜-, and ½-inch drives. The ½-inch drive is the most popular and versatile size for automotive applications.

There is no definitive answer to this question as it depends on your specific application and the condition of the materials being fastened. In many situations, you can apply torque to either the nut or the bolt head and both will result in a tight connection. However, neither will necessarily avoid breakage more often – that occurrence can be avoided through other means.

Should you click a torque wrench twice

When you’re tightening a bolt, one click is enough. Many users allow their wrenches to click more than once, but this means they’re applying added torque to the bolts. Use your tool in a smooth, steady fashion and let it click just once.

You don’t need a great torque wrench for lug nuts. The precise torque isn’t as important as making sure that all the lugs on a wheel are tightened to the same degree so the load is evenly applied. For most cars, I use 90 lbs -feet, and 100 on light trucks using a slightly larger diameter lug.

What happens when you over torque a screw?

When it comes to bolts, torque is everything. Too little torque and the bolt will deform, potentially leading to leaks or other problems. Too much torque and the bolt will break. That’s why it’s so important to use a torque wrench when installing bolts, to ensure that they’re tightened to the correct specifications.

There are two main types of screws – Phillips and Torx. Phillips screws are designed to move in two dimensions and force the screwdriver to always be in the center. However, they tend to slip easily and wear quickly. Torx screws are superior because they fit much more snugly. However, they can be less forgiving if you use the wrong size of screwdriver.

Conclusion

There is no definitive answer to this question as different people have different preferences. However, many users report that the Milwaukee Electric Tools 3/8-Inch Drive Electronic Torque Screwdriver is one of the best torque screwdrivers available on the market. This tool is designed for precision and accuracy, and is capable of torqueing screws between 10 and 50 in-lbs.

From what I can find, it seems that the best torque screwdriver is the one that fits your needs the most. There are a lot of different factors to consider when choosing a torque screwdriver, such as the size and shape of your screws, the amount of torque you need, and the type of material you’re working with. You should also consider the price and quality of the screwdriver itself. Ultimately, the best torque screwdriver is the one that will help you get the job done right.