If you’re looking for a way to harden your screwdriver tip, there are a few things you can try. One option is to heat the tip of the screwdriver with a blow torch until it’s red hot, then quench it in oil. This will make the tip harder and more resistant to wear. Another option is to file the tip of the screwdriver to a sharp point. This will also make it easier to penetrate hard materials.

There is no one-size-fits-all answer to this question, as the best way to harden a screwdriver tip will vary depending on the materials you are using and the desired outcome. However, some general tips on how to harden a screwdriver tip include:

– Using a hardening agent: This could be anything from a simple household substance like vinegar, to a more specialized product like a quenching oil.

– Applying heat: This could be done using a blow torch, or even just a lighter.

– Hammering: This will help to compact the metal and make it more dense, which will in turn make it harder.

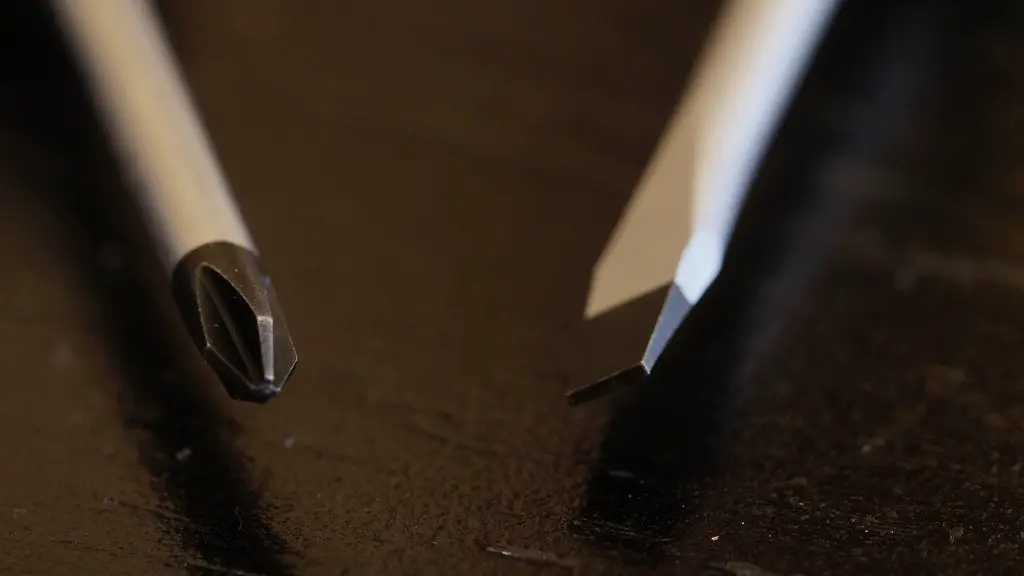

How do you harden a screwdriver bit?

Heat treatment by quenching and tempering is the most effective treatment for steel used for screwdriver bits. This treatment involves heating the steel to a high temperature and then cooling it rapidly. This process strengthens the steel and makes it more resistant to wear and tear.

The screw driver blade is heated, slowly at first, warming up the whole blade. Then the heat is concentrated on the area at the end of the blade. This gradually becomes ‘red’ hot.

What is the best way to restore a screwdriver tip

Sharpening your tools is a great way to keep them in good condition and prolong their lifespan. Using a sharpening stone or emery paper is a simple way to achieve this. Just start gently on one side and then flick the tool the other way to grind the other side. Continue until you get an even grind on both sides.

In order to harden steel fasteners, they are first heated to a high temperature in order to convert their structure into austenite. They are then quenched or rapidly cooled in water, oil, or air. This process results in the transformation of the steel’s crystal structures into martensite, which is much harder than the original austenite.

How do you get more torque on a screwdriver?

The screwdriver has a scale on the nose which is matched to the torque curve setting required for your assembly application. Turning the knob to the right will increase torque and left will decrease torque.

If you want to soften the steel and relieve any built-up stresses, you’ll need to heat it up again – this time to 400℉. This process, known as tempering, can be done over a fire or using a blowtorch, but the simplest method is to put it in your oven at 400℉ for two one-hour cycles, letting the knife cool between each one.

What is difference between hardening and tempering?

Hardening of a steel grade increases its hardness, but also reduces its toughness. Tempering the steel grade restores some of its hardness, but also increases its toughness. This is because tempering changes the microstructure of the steel, altering the balance of hardness and toughness.

If you’re looking for a way to save money on your next set of screwdrivers, consider magnetizing your existing ones instead! Rare earth magnets (or any other large magnets) can easily be used to magnetize the tips of your screwdrivers, giving them the same benefits as if you had purchased a new set. Simply brush the end of your screwdriver across the magnet a few times — and you’re good to go!

How are blades hardened

Hardening is a way of making the knife steel harder. By first heating the knife steel to between 1050 and 1090°C (1922 and 1994°F) and then quickly cooling (quenching) it, the knife steel will become much harder, but also more brittle.

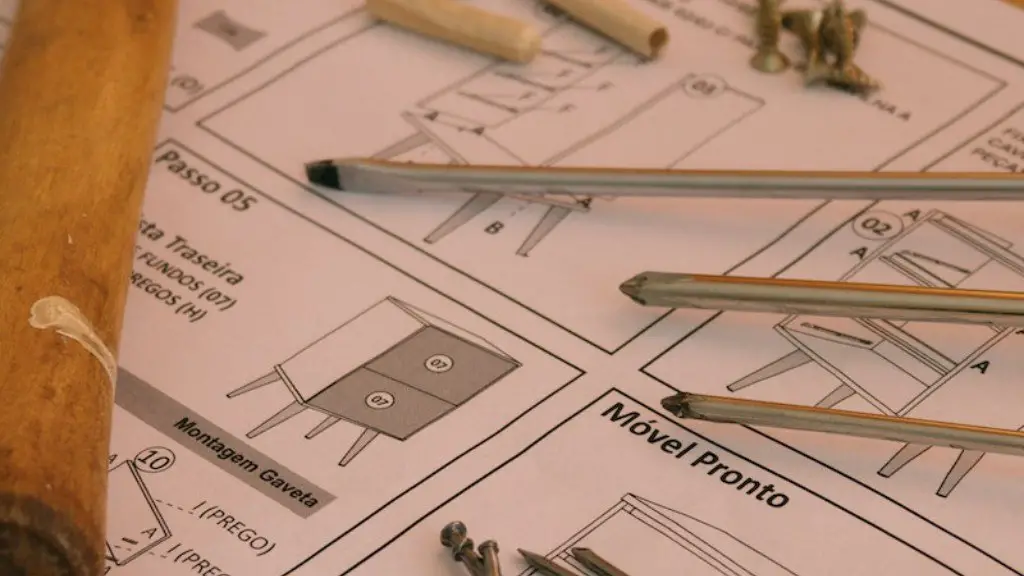

A rounded tip on a screwdriver should be filed down so that the edges are straight. This will help to ensure that the right screwdriver is selected for the job at hand and that the screwdriver handle is clean. A greasy handle can cause accidents, so it is important to keep it clean.

Why is my screwdriver stripping?

drilling into something without the right size drill bit can cause irreversible damage. Over tightening a screw can cause it to break. using an old and warn drill bit can cause it to slip and not drill correctly.

You can magnetize a screwdriver by stroking it along the length of a permanent magnet. This north-south alignment of the atoms in the screwdriver will make it a temporary magnet. You can demagnetize a screwdriver by heating it up to about a thousand degrees Fahrenheit.

How do you temper metal

Hardening is a process of heat treatment, which makes a metal harder. However, the metal becomes more brittle as well. Tempering is usually performed after hardening, in order to reduce some of the excess hardness and make the metal less brittle. It is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

Hardening is a heat treatment process that is used to toughen and strengthen metals. The process involves controlled heating to a critical temperature, followed by controlled cooling. Depending on the type of material, the appropriate cooling rates can vary from very fast (water quench) to very slow (air cool).

How do you heat treat metal to make it stronger?

If you’re looking to harden your steel, one method is to put it in an oven for three hours. During the tempering process, the steel will soften the alloys inside to make it less brittle. If you need to use a blow torch, focus the flame tip on the area you want hardened. Keep heating the steel until you notice a blue color form on the metal.

If you need to apply a lot of torque to a screw, then a hand screwdriver is probably your best option. This is because hand screwdrivers can deliver up to 120 lbfin of torque, which is more than enough for most applications.

Can you torque from Phillips head

The study found that the Phillips bit design allowed subjects to exert the maximum torque and the minimum axial force. Although there was no significant effect, the data suggests that this design is more efficient than other designs.

A longer driver means that the angle for a given wobble is less. This means that the driver stays in its slot at higher torque. This is because the longer the driver, the more force it can exert on the wheel, and the more force it can exert on the wheel, the less chance there is for the wheel to wobble.

Final Words

There are a few ways to harden the tip of a screwdriver. One way is by heating the tip with a torch and then quenching it in oil. This will harden the tip and make it more durable. Another way is to use a hardening compound. This will coat the tip and make it harder.

If you want to harden the tip of your screwdriver, you can do so by heating it up and then cooling it down quickly. This will make the metal harder and less likely to break.