One of the most frustrating things that can happen when you’re trying to screw in or out a screw is stripping the head of the screw. This usually happens when you’re using a screwdriver that is too big or too small for the screw head. In order to avoid stripping screws, it’s important to use the right size screwdriver. If you’re not sure what size to use, err on the side of using a smaller screwdriver. It’s also important to apply enough pressure to the screwdriver so that it doesn’t slip out of the head of the screw.

There are a few ways that you can avoid stripping screws with your screwdriver. One way is to make sure that you are using the correct size screwdriver for the screw that you are trying to remove. Another way is to use a screwdriver with a magnetic tip so that it will grip the screw more securely. Finally, you can try using a socket wrench to remove the screw instead of a screwdriver.

How do you not strip a screw with a screwdriver?

Emmons’ five-step plan to avoid screwing up:

1. Drill pilot holes to keep screws from seizing up in wood. First drill a hole to the same depth as your screw with a bit barely thinner than the screw’s shank.

2. Use a fresh driver bit.

3. Use the clutch.

4. Squeeze the trigger firmly.

5. Keep the pressure on.

When working with screws, it is important to take your time and be careful. Turning the screws at an angle can cause them to strip, and using the incorrect sized screwdriver (or drill bit) can also damage the screw. Be sure to use the correct sizes and take your time to avoid any damage.

How do you stop a screw from stripping

If you’re looking to prevent stripped screws, there are a few things you can do. First, make sure you’re using the correct bit size for your screw. Second, get rid of any beat-up driver bits you may have. Third, apply adequate and constant pressure when driving the screw. Fourth, create a pilot hole before driving the screw. And fifth, use a bit holder to help prevent stripping.

There are a few key differences between square drives, Phillips drives, hex screws, and Torx screws. For one, square drives and Phillips drives offer four points of contact, while hex screws and Torx screws offer six. This makes hex screws and Torx screws less likely to strip than square drives and Phillips drives. Additionally, hex screws and Torx screws are less likely to slip out of the driver than square drives and Phillips drives.

What is the best screw head to prevent stripping?

Phillips head screws are designed to help prevent stripping from happening as easily as it would with a slot head screw. The more complicated the screw head and its driver are, the more secure the driver will be in the screw and the less likely that stripping will occur.

Stripping occurs when the screw drive becomes damaged and the driver no longer engages properly with the screw. This causes the screwdriver or drill to slip and rotate within the drive, rather than drive the screw.

Can you fix a stripped screw?

If you have a stripped-out screw hole, you can fix it by applying wood glue to a few toothpicks and inserting them into the hole. Once the glue dries, you can cut off the protruding ends of the toothpicks and drive the screw into the hole. Just be careful not to overtighten the screws or you’ll strip the hole again.

A stripped screw is one in which the slots in the head of a screw have worn out. This makes it hard for a screwdriver to grip the screw and turn it. Stripped screws are usually old screws that have been screwed in and out for a long time. You can also strip a screw by overtightening it.

Are Phillips screws designed to strip

This is a myth that has been perpetuated in order to sell more screws. The idea that these screws were designed to cam out is simply not true. The cam out feature was actually designed to protect the expensive machined parts from being damaged by unskilled laborers who would over tighten the screws.

Left-handed threads are used in some applications where a right-handed thread would be problematic. For example, left-handed threads are used on the pedal threads of bicycles so that the left pedal will not unscrew when riding.

What do you wrap around a stripped screw?

In Perfect, the little piece of cable tie fills the hole and prevents the water from coming in.

Next, add a spring washer on top of the flat washer. The spring washer will help to absorb vibrations and keep the screw tight.

What to do when a metal screw hole is stripped

Tapping is a process of cutting internal threads in a hole using a taps. It is done using a hand tool ormachine. The first step is to drill a pilot hole slightly smaller in diameter than the outside diameter of the tap. Operating the tap handle, the tap is then screwed in until it bottoms. Lubricant is then applied to the threads and the handle is turned to the left (counter-clockwise) to cut the threads. The tap is given 1/4 to 1/2 turns before being backed out (turned in the clockwise direction) slightly to clear the chips (the metal shavings). This process is repeated until the hole is completely tapped.

If you have a stripped screw, you can use the duct tape trick to remove it. Cover the stripped screw head in duct tape and fit your screwdriver into the groove on top of the tape. Apply pressure and turn counterclockwise. The tape should fill in the gaps making it easy to remove the screw.

Can you hammer in a stripped screw?

If you’re having trouble getting a grip on a stripped screw, try using a hammer to tap the handle of a manual screwdriver into the screw. This can give you the extra traction you need to loosen or remove the screw.

If you have a stripped screw, you can try gluing it. First, fill the stripped head of the screw with a glue like epoxy or hot-melt glue. Then, stick the screwdriver in and wait for the glue to dry or cool. Finally, apply even pressure as you rotate the screw.

How do you get a Phillips head screw out without stripping it

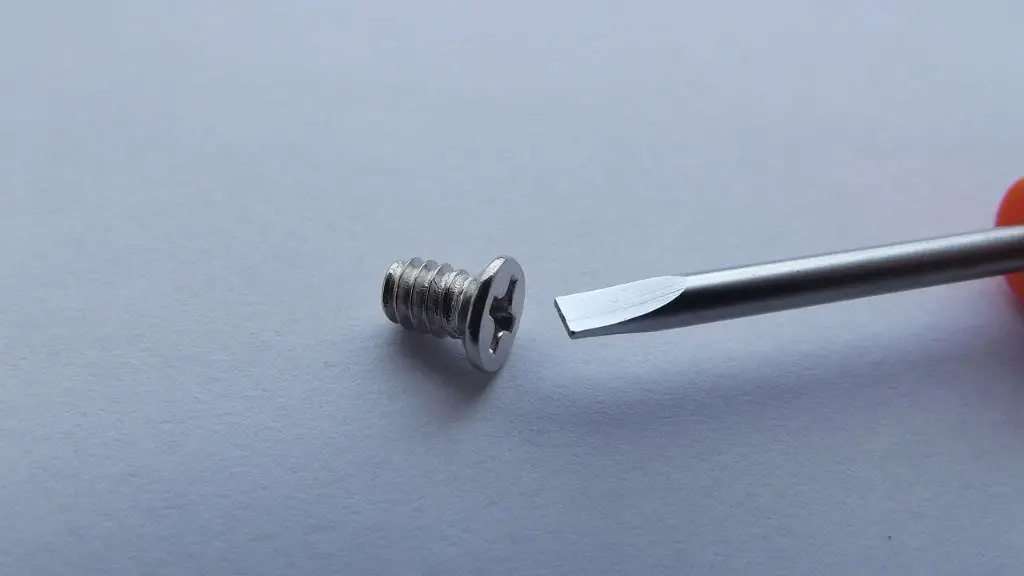

If you’re trying to remove a Phillips head screw and having trouble, try using a manual flat-head screwdriver instead. By pressing hard, you may be able to dig into the stripped head and remove it by angling the screwdriver. All you need to do is raise the screw by 1/8-inch in order to be able to switch over and extracting the screw with pliers.

If you need to remove a Phillips screw, use a impact driver tool. First, get a solid grip on the impact tool. Then smack the end with a hammer. The blow automatically forces the Phillips bit into the screw head and twists it at the same time.

Conclusion

There are a few ways to avoid stripping screws with a screwdriver. One way is to use a screwdriver that fits the screw snugly. Another way is to use a screwdriver with a softer tip, such as one made of rubber. Finally, you can use a screwdriver with a lower torque setting.

To avoid stripping screws with a screwdriver, you need to keep the screwdriver tip centered on the screw head and use slow, steady pressure while turning the screwdriver.