Pliers are a hand tool used for holding objects or materials together, or for bending and cutting wires. There are many different types of pliers, including needle-nose pliers, slip-joint pliers, and locking pliers. Each type of plier is designed for a specific purpose. Pliers are made from a variety of materials, including steel, aluminum, and plastic. The manufacturing process for pliers begins with a piece of steel that is cut to the desired shape and size. The steel is then heat treated to improve its strength and durability. Next, the steel is machined to create the handle, jaws, and cutting surfaces. The pliers are then finished with a coating of paint or other protection.

The most common type of pliers, called flat-nose or needle-nose pliers, are made by first cutting a strip of steel to size. This strip is then formed into the basic plier shape and the handles are riveted on. The cutting jaws and gripping jaws are then cut from a piece of hardened steel and fitted onto the handles.

How are pliers built?

There are many different types of pliers, but they all follow the same basic design. Pliers typically have two metal jaws, with the fulcrum (pivot point) located closer to one end. This creates shorter jaws on one side of the fulcrum, and longer handles on the other side. Pliers are used for a variety of tasks, including gripping, cutting, and bending.

There are two main types of pliers: those made from alloyed tool steel, and those made from unalloyed tool steel. Alloyed tool steel pliers are made from steel that contains various alloying elements, such as chromium, vanadium, and molybdenum. This type of steel is more durable and resistant to wear and tear than unalloyed tool steel. Unalloyed tool steel pliers are made from steel that contains a relatively low carbon content (usually 0.45%). This type of steel is less durable than alloyed tool steel, but is more affordable.

What metal is best for pliers

When choosing a pair of pliers, the material they are constructed from is an important consideration. Nickel chromium steel or chrome vanadium steel are well-known materials that are often found in good quality hand tools. These materials are hard-wearing and durable, meaning that the pliers are more likely to last a long time, even with heavy use.

These textured grips provide a slip-resistant grasp that is designed for use with plier handles. They are made of rigid plastic and can be installed by using soapy water.

Why do pliers have teeth?

Slip-joint pliers are versatile tools that are used for gripping and bending hardware. They have two levels of teeth; the fine teeth located near the front are designed for gripping small objects and nails, while the coarse teeth located toward the back are designed for gripping bulky nuts and bolts. Slip-joint pliers are also equipped with a slip joint that allows the jaws to open wider or narrower, depending on the size of the object being gripped.

If you’re frequently fishing in saltwater, it’s important to take care of your fishing pliers to prevent them from rusting. Moisture from the air can also cause the joints to jam, so make sure to keep them clean and dry.

Do pliers have teeth?

Slip-joint pliers are one of the most common types of pliers. They have two sets of teeth on their jaws: fine and coarse. The fine teeth are useful for grabbing smaller items such as nails. Meanwhile, the coarse teeth are good for grasping large things such as nuts or bolts.

William Petersen was a Danish immigrant who came up with the idea for locking pliers while working in his blacksmith shop. He began selling them from the trunk of his car to farmers and people in surrounding towns, and eventually patented his idea and called it Vise-Grip. Today, Vise-Grip is a well-known brand of locking pliers, and Petersen’s invention has helped countless people with their DIY projects.

Can pliers cut steel

Diagonal pliers are generally used for cutting wire and other materials. They can be used for cutting copper, brass, iron, aluminium, and steel wire. However, lower quality versions of diagonal pliers are not generally suitable for cutting tempered steel, such as piano wire. This is because the jaws of lower quality diagonal pliers are not hard enough.

Pliers are often misused as general-purpose tools. Their use should be limited to operations for which they were designed: gripping and cutting (never for loosening or tightening nuts). Always use wrenches on nuts and bolt heads, never use a pliers.

What should you not do with pliers?

If you follow these simple rules, your pliers should last you a long time. Excessive heat can damage the temper of the steel, so avoid using them near a forge or other intense heat source. Bending stiff wire with the tips of the pliers can cause them to break and should be avoided. When cutting wire, apply even pressure and don’t rock the pliers side to side, as this can damage the jaws. Finally, never use the nose of the pliers as a pry bar, as this can cause them to distort and no longer meet flush when closed. With a little care, your pliers will give you years of faithful service.

These line cutters are great for cutting braided line, monofilament line, and fluorocarbon line. They feature line cutters, crimp sleeves, a crimp split lead, and a split ring in the nose. Aluminum is rust-resistant and this tool can be used for both fresh and saltwater fishing.

What is a monkey plier

These hardened teeth are designed to grip from any angle, making them ideal for tightening, clamping, twisting and turning. They’re available in two sizes, 10 and 12 inches.

When it comes to pliers, size does matter. Smaller pliers are good for delicate work, but they lack the grip and jaw capacity for a heavy-duty project. Large pliers are great for heavy-duty work, but they can easily damage light-duty materials. Generally speaking, pliers in the 8- to 12-inch range are the most useful.

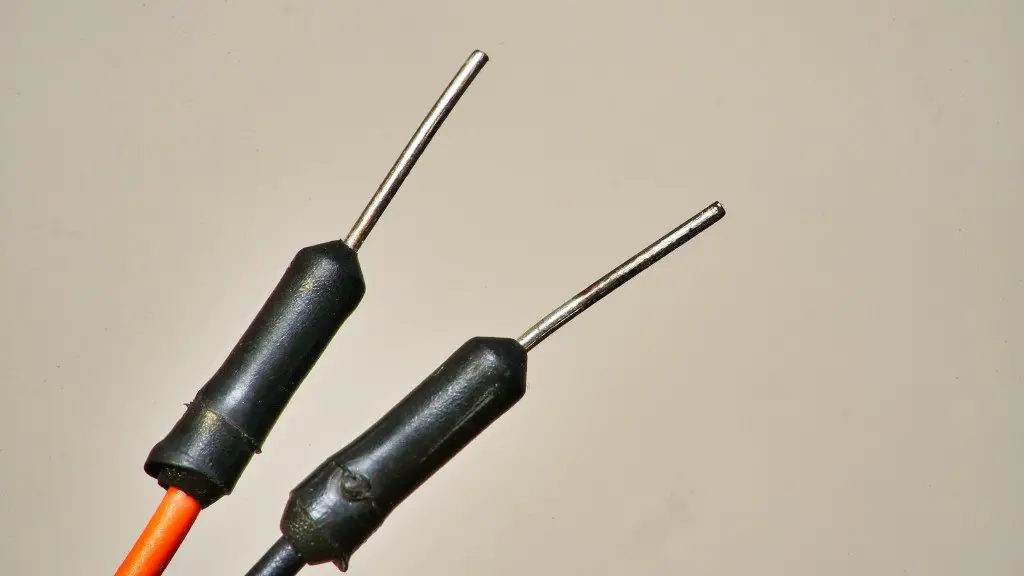

Why are pliers insulated?

Hand tools that are properly insulated help protect workers against electric shock and arcing. This type of protection is important because it can help prevent injuries and damages to equipment.

If you’re looking to get a tooth extracted, it’s important to know that there are right and wrong ways to go about it. Trying to yank the tooth out with a pair of pliers or another tool is likely to crush the tooth, which will make it much more difficult (and expensive) to repair. The best course of action is to consult with a dentist or oral surgeon and have the tooth removed professionally.

Can you hurt yourself with pliers

There are a few different types of pliers that are commonly used. Adjustable or slip-joint pliers are two of the most common. Needle-nose pliers, channel-lock pliers, lineman’s pliers, vise grips, and diagonal- or side-cutting pliers are all types of pliers that are used for different purposes.

Most plier-related injuries involve lacerations to the hands and fingers. US Consumer Product Safety Commission data shows that these injuries are most common. To avoid injuries, it is important to use the right type of pliers for the job and to be careful when using them.

If you’re feeling brave, or if you absolutely have to, then here’s how to do it:

-Wash your hands and the area around the tooth.

– sterilize a pair of needle-nosed pliers with boiling water.

– place the pliers around the tooth and grip it firmly.

– twist the pliers slowly until the tooth comes out.

But please, see a dentist if you can.

Warp Up

Assuming you would like a response to the question:

How are pliers made?

Pliers are a tool that many people use on a day-to-day basis without giving much thought to how they are made. Pliers are made by taking a piece of metal and adding ridges or patterns to the grip area. This can be done by machine or by hand. The joint of the plier is then formed by heating the metal and bending it into shape. The handles are then added and the pliers are ready to be used.

There are many steps in the process of making pliers, but it can be generally broken down into four main stages: stamping, bending, riveting, and finishing. First, a piece of metal is cut into the shape of the pliers using a stamping machine. This metal is then heated and bent into the desired shape. Next, the jaws of the pliers are riveted together using a thicker piece of metal. Finally, the pliers are polished and any handles are added.