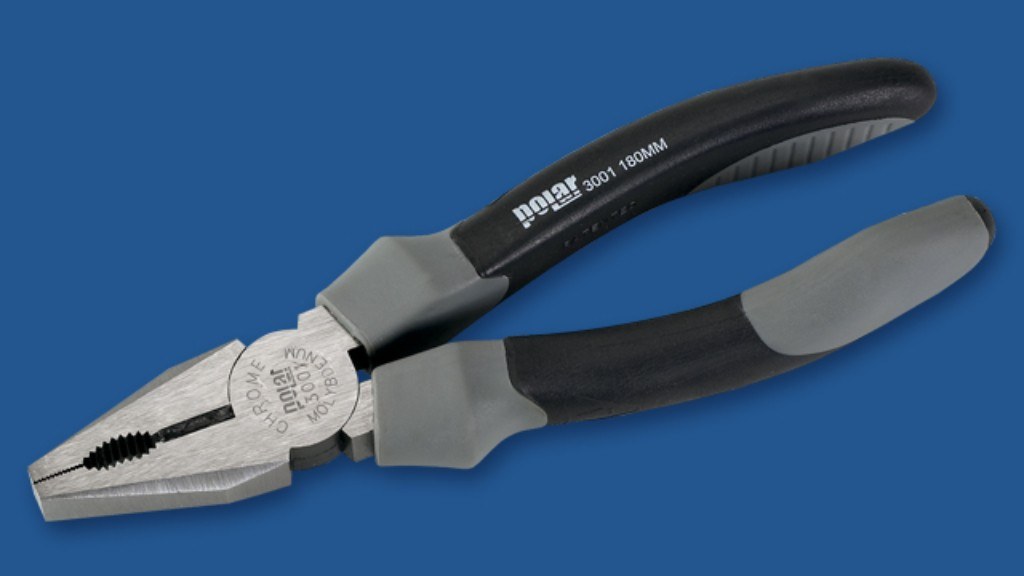

If you work with electrical wiring, then you’ve probably used crimping pliers before. But what are these tools actually for? Crimping pliers are a type of hand tool that is used to join two pieces of metal together. The jaws of the pliers are serrated, which helps to grip the wire. The pliers also have a built-in cutter, which is used to trim the excess wire. Crimping pliers are a quick and easy way to create a strong connection between two pieces of metal.

Crimping pliers are used for creating a tight join between two pieces of metal. The jaws of the pliers have a ridged or grooved surface that helps to grip the metal and create a strong seal.

Do I need crimping pliers?

If you’re looking to add a little extra security to your design, or want to make sure your crimp beads look smooth and professional, then regular crimping pliers are a must-have tool. These pliers allow you to compress 2x2mm or 2x3mm crimps, making them extra secure. Plus, the easy-to-follow instructions in our Tips and Tricks section make using them a breeze.

Crimping is a great way to secure wire and clasps onto jewelry. It’s quick and easy, and gives a nice, clean finish. Here’s how to do it:

1. Thread a crimp onto your wire.

2. Loop the wire around your clasp or jump ring.

3. Squash the crimp with flat nose pliers, or use speciality crimping pliers to “fold” the bead into a small volume.

4. Trim any excess wire.

That’s it! Your crimp will keep everything nice and secure.

Do you really need a crimping tool

A crimper is an essential tool for creating professional-looking electrical connections. Without a crimper, it would be difficult to properly secure the locking tab on an electrical connection, making it more likely to come loose over time. With a crimper, you can ensure that your electrical connections are strong and long-lasting.

The crimping process is important to ensure that the wire is securely fastened within the terminal. This will help to prevent the wire from falling out or being pulled out.

Is it better to solder or crimp?

Crimped connections are more flexible and heat-resistant than soldered ones, and they have greater potential for wire fatigue and stiffening. Crimping is often more consistent than soldering, which can vary according to method or technician.

Crimping is a stronger and more reliable way to connect two pieces of metal than soldering. When you solder, you use heated metal to join the cable to the connector. Over time, the metal filler will degrade and this can cause the connection to fail. Most electricians will agree that crimping is also easier than soldering.

How do you use wire crimping pliers?

You would next take your wire And insert it you’ll see how it’s sticking through just like we’re going to do with the other side take the other end of the wire and insert it in as well and then take your voltmeter and put the negative lead on the ground to which ever one you’re testing and put the positive lead on the top of the wire and you’ll see that it’s connected now if you want to test the other side

The end of the barrel is where the wire and terminal are inserted into the crimping tool. If your crimping tool does not have a built in wire cutter, you will need to use a separate wire cutter to trim the wire to the correct length before inserting it into the barrel. Once the wire is inserted, you will need to use the crimper to compress the barrel around the wire to create a secure connection.

Why do we crimp wires

Crimped connections are ideal for creating a long-lasting, reliable seal between a connector and a cable. This seal is protected from environmental conditions such as moisture, sand, dust, and dirt.

Crimping of solid wire, component leads, or stranded wire that has been solder-tinned, is prohibited. The wire ends shall be visible. The conductor should extend a minimum of even with, and a maximum of one wire diameter beyond, the conductor crimp edge.

Which is better crimp or clamp?

PEX pinch clamps are a great way to make connections in tight spaces. The smaller jaws of the pinch clamp tools make it easier to work in smaller spaces and the PEX is less likely to be damaged in the process.

And then spray your flexible holding spray before you start to crimp. Pay attention to how high up on the can you are spraying. You don’t want to get too close and risk inhaling the fumes.

What are the disadvantages of crimping tool

There are a few disadvantages to using crimp-on connectors. First, once crimped, the connection cannot be undone. This means that if there is an issue with the connection, the entire connector assembly will need to be replaced. Additionally, unless crimped with the proper dies and handles, the connection can be poor and may eventually fail.

It is not advisable to use pliers to crimp wires because crimping process requires a lots of pressure and a pliers can not afford that amount of pressure to crimp a bunch of multi-strand wires in one go.

What are the two types of crimp?

There are two main types of crimps – open barrel and closed barrel. Open barrel styles are typically used for terminals that will be exposed to vibration and corrosion, while closed barrel styles are better suited for high-volume applications.

A crimp connector is a type of electrical connector used to terminate stranded wire. The benefits of using a crimp connector instead of soldering or wire wrapping include:

-A well-engineered and well-executed crimp is designed to be gas-tight, which prevents oxygen and moisture from reaching the metals (which are often different metals) and causing corrosion.

-Crimping is typically faster than soldering or wire wrapping.

-Crimping leaves a neater connection than soldering or wire wrapping.

Should you tin wires before crimping

These standards exist to ensure the longevity and effectiveness of crimp terminations, screws, and mesh splices. Tinned wire is more susceptible to breakage under pressure, which could cause serious problems down the line. It’s better to be safe than sorry, so follow the standards and avoid using tinned wire in these applications.

There are a few things you can do to relieve cramps:

1. Massage the affected muscle

2. Apply heat or ice

3. Take a warm bath

4. Stretch the muscle

5. Take over-the-counter pain medication

Final Words

Crimping pliers are used for a variety of tasks, including:

-Cutting and stripping wire

-Crimping terminations onto wire

-Making loops in wire

-Pressing release tabs on electrical connectors

Crimping pliers are a type of tool that is used to compress a metal sleeve or ferrule onto a wire in order to create a secure connection. This type of connection is often used in electrical applications where a strong, long-lasting connection is required.