A cordless drill is one of the most versatile and useful tools you can own. With the right attachments, you can use it for everything from drilling holes to driving screws. In this article, we’ll show you how to use a cordless drill as a screwdriver.

There are several ways to use a cordless drill as a screwdriver. One way is to use the drill to power the screwdriver. Another way is to use the drill todrive the screwdriver.

How do you attach a screwdriver bit to a drill?

The most important thing to remember when you’re installing a bit is to make sure that the bit is the right size for the horse’s mouth. If the bit is too small, it will pinch the horse’s lips; if it’s too large, the horse won’t be able to close its mouth properly.

To use a drill for inserting a screw into a pilot hole, follow these steps:

1. Power up the drill

2. Adjust the torque so it’s low

3. Fit the screw into the slot on the drill bit

4. Line up the screw with the hole

5. Make sure the drill is vertical

6. Pull the trigger on the drill and press gently into the screw

With these steps, you’ll be able to insert a screw into a pilot hole using a drill. Be careful not to over-tighten the screw, or you may strip the hole.

How do you drill a screw with a cordless drill

When drilling into wood, it is always best to first drill a pilot hole. This will help to prevent the drill bit from slipping and will make it easier to drive in the screw. To do this, simply use a drill bit that is a few sizes thinner than your screw. Then, simply drive in the screw until it is snug against the material.

We’re going to do is insert the drill bit into the chuck making sure to align the flats on the drill bit with the flats in the chuck. Then we’re going to tighten the chuck by hand until it’s snug.

What are screwdriver bits for drills called?

Driver bits are amazing accessories that can turn your drill into a power screwdriver. They allow you to drive and remove screws quickly and efficiently, and can make your work go much more quickly. I highly recommend investing in a set of driver bits!

There are three styles of screwdriver bits available:

1. Standard: The standard screwdriver bit is the most common type, and is designed for use with standard screws.

2. Phillips: The Phillips screwdriver bit is designed for use with Phillips screws.

3. Torx: The Torx screwdriver bit is designed for use with Torx screws.

Can you use an impact driver as a screwdriver?

When using a drill to drive screws into wood, you need to be careful not to damage the screws. Small screws are especially susceptible to damage, so you may be better off using a screwdriver by hand for delicate screws.

There is no definitive answer as to whether you should or shouldn’t drill a pilot hole before driving a screw. It depends on the type of screw you’re using and the project you’re working on. If you’re unsure, it’s best to err on the side of caution and drill a pilot hole.

What’s the difference between an electric screwdriver and a drill

An electric screwdriver is a versatile tool that can be used in a variety of applications. It is designed to drive screws in tight spaces where a drill can’t fit and its size also makes it easier to store.

If you’re working with metal, you’ll need to use a self-tapping screw. These screws are designed to tap their own threads into metal, and they do not require a pilot hole. However, self-tapping screws cannot drill through metal and will require a pilot hole. If you’re working with wood, you can use either a self-drilling or self-tapping screw. These screws are designed to drill their own pilot holes, so you won’t need to drill a hole beforehand. However, self-drilling screws cannot tap their own threads, so you’ll need to use a self-tapping screw if you’re working with metal.

How do you put a bit in a cordless drill?

The dental drill is a tool that is used by dentists to remove tooth decay and shape tooth enamel. The drill has a drill bit that is inserted into the mouth and rotated at a high speed to remove the tooth decay. The drill also has a suction tube that is used to remove the tooth decay and saliva from the mouth.

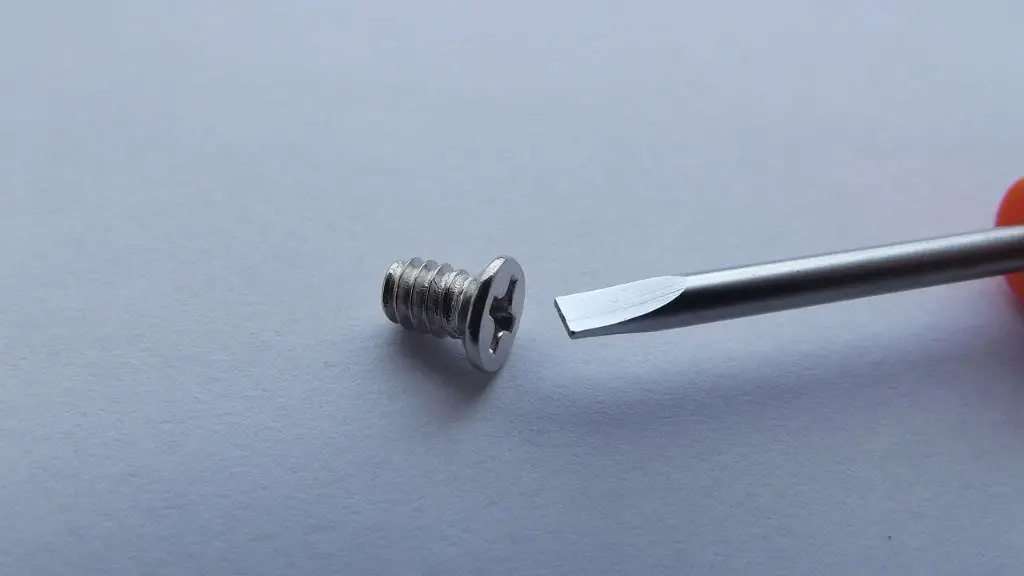

We will now remove the Phillips screw with even pressure.

How do you put a screwdriver bit in a Milwaukee drill

When you are creating a 3D object with a hexagon shape, it is important to line the faces of the hexagon up with the three sides of the object. This will ensure that the object is symmetrical and looks correct from all angles.

Cordless screwdrivers are a handy tool to have around the house for light maintenance and DIY projects. They are small and portable, making them easy to use in tight spaces. Plus, they come in handy for those hard-to-reach places.

Which is bigger #1 or #2 Phillips?

Phillips head screwdrivers come in sizes from 0 to 4. The lower the number, the larger the tip. Most jobs can be handled by a No 2, like this 7-inch option from Klein.

A Phillips screwdriver is a hand tool used to drive screws with a Phillips head. It is named after its inventor, Henry F. Phillips.

Do cordless drills have a keyed chuck

Chuck is one of the main of features cordless drill. Some chucks need to use a key to turn the sleeve. These are called “key” slits. Most hand drills and braces, however, use a keyless slit, where the sleeve or shell is tightened by hand.

There are three settings on most drills and each is meant for a different task. Setting 1 is low speed/high torque and is best for driving screws. Setting 2 is a medium speed/torque and can be used for drilling or driving. Setting 3 is the highest speed and is meant for drilling or driving fasteners.

Final Words

To use a cordless drill as a screwdriver, you will need to set the drill to the correct speed and then use the drill bit to drive the screw into the material.

A cordless drill is a versatile home improvement tool that can be used for various tasks, including driving screws. When using a cordless drill as a screwdriver, it is important to first determine the type of screw that you are using. For example, wood screws have different head types than machine screws. Once you have determined the type of screw, you can then use the appropriate drill bit. Be sure to also use the correct drill speed for the type of screw that you are using.