There are a few different ways that you can go about determining the size of spanner that you will need. One way is to simply measure the distance across the bolt that you are wanting to loosen or tighten. Another way is to use a caliper or ruler to measure the thickness of the bolt. Once you have these measurements, you can then reference a spanner size chart to determine the size of spanner that you need.

There is no definitive answer to this question, as the appropriate spanner size will vary depending on the specific application. However, a few general tips on how to determine spanner size include:

– Checking the manufacturer’s specifications for the recommended spanner size

– Using a spanner that is the next size up from the bolt or nut being tightened or loosened

– Trial and error, starting with a smaller spanner and moving up to a larger one if needed

How do I know what size nut spanner I need?

As you can see, it is best to know the thread type of the nut and then choose the spanner size that will then give the best fit. Once you know the thread type and size of the nut, then it is simple to look up the correct spanner size.

There are different spanner (wrench) sizes for different metric screws. The table above provides a rough guide for some of the most common sizes.

What size is a 3/8 spanner in mm

There are a few different ways to convert between US inches and metric mm wrench and spanner sizes. One way is to use a conversion chart, which will list the sizes in both units of measurement. Another way is to use a calculator that can perform the conversion for you.

There is 1 spanner of each size: 1/4 inch – 5/16 inch – 3/8 inch – 7/16 inch – 1/2 inch – 9/16 inch – 5/8 inch- 11/16 inch – 3/4 inch – 13/16 inch – 7/8 inch – 15/16 inch.

How do I choose the right spanner?

There are various types of spanners available in the market, but the one with a thicker and wider head is considered to be stronger than the others. This is because the thicker head provides a better grip and hold, which helps to turn nuts or bolts easily without damaging them.

M6 fasteners usually require a 10mm spanner, M8 a 13mm spanner, M10 a 17mm spanner and M12 a 19mm spanner.

Is 10mm metric or SAE?

What is the metric conversion for 3 8 to mm?

3/8″ = 10mm. 1/2″ = 13mm. 9/16″ = 14mm. 5/8″ = 16mm.

How do I convert to mm?

How to convert millimeters to inches?Enter the value you want to convert in millimeters in the top field (the one labeled “mm”).As you start typing, the drop down menu will appear with possible units. … The converter also works the other way round: if you enter the value in inches in the “in” field, the equivalent value in millimeters is calculated and displayed.More items…

What is 3/8 called in metric?

Standard / Metric Wrench Conversion ChartBolt DiameterStandardMetric3/8″9mm7/16″11mm1/2″13mm9/16″14mm39 more rows

Is 3/8 and 10mm the same?

3/8 hex key is the same as 10mm metric. 1/4 hex key is the same as 6mm metric.

Why is metric better?

Why Use the Met

The M10 x 25 is a screws with a 10 mm diameter and a coarse thread.

Is a 10mm nut M10

Metric threads are eithercoarse or fine, and are designated by a capital M, followed by the nominal outer diameter of the thread in millimeters (mm). For example, an M10 x 1.5 thread has a 1.5 mm pitch (the distance between adjacent threads), and an M12 x 1.75 thread has a 1.75 mm pitch.

Knowing the relationship between bolt diameter and head/wrench size can be helpful when assembling or disassembling a project. For example, if a 3/8″ bolt is needed, a 9/16″ wrench or socket should be used. Refer to the table for other diameter and head/wrench size combinations.

What is SAE spanner size?

SAE (Society of Automotive Engineers) is a form of measurement used primarily on cars made in the USA. This is why more often than not, if you’re in the United States, you’re most likely finding wrenches and sockets in SAE sizings. AE sockets are sized in inches and fractions of inches.

What is the size of metric to inches?

Metric to Standard/Imperial chart for small sizesMetric (mm)Size (inches)2mm0.0787″3mm0.1181″4mm0.1575″5mm0.1969″21 more rows

How do you convert metric to Imperial torque?

How To Use The Torque Conversion ToolSelect the unit to convert from in the input units dropdown.Select the unit to convert to in the output units dropdown.Enter the value to convert from into the input box on the left.The conversion result will immediately appear in the output box on the right.More items…

How do you convert metric to Imperial?

Let’s look at an example. There are 2.54 centimeters in one inch (cm=in). So we know that 1in=2.54cm. We can find the measurement of 2 inches by multiplying 2 by 2.54: 2(2.54)=5.08.

Which is bigger metric or standard?

This includes tools such as wrenches, sockets, saw blades, drill bits, etc. Metric tools are Size 00 through Size 50 –

What is a spanner called in America

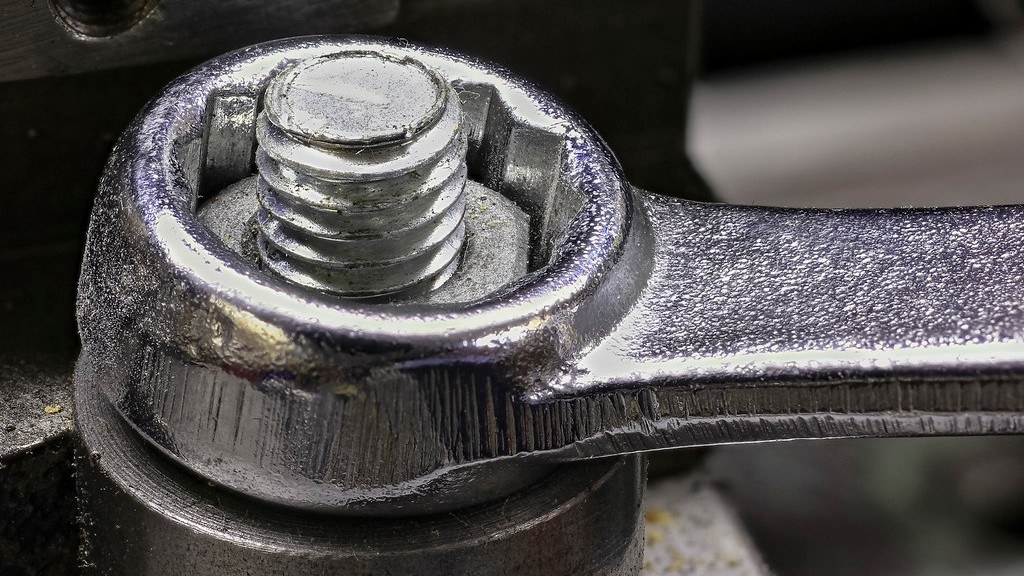

A wrench is a tool used to grip and turn objects such as nuts and bolts. The most common shapes are called open-end wrench and box-end wrench. In American English, spanner refers to a specialized wrench with a series of pins or tabs around the circumference.

A spanner is a type of adjustable wrench that is used to tighten or loosen nuts and bolts. In North America, the word “spanner” is used interchangeably with “wrench.” If Americans want to ruin something, they say they are “throwing a wrench into it.” In Britain, the phrase “throwing a spanner in the works” is used to describe the same thing.

What is the most common used spanner?

Open end wrenches are one of the most common types of spanner or wrench. The C-shaped, open ended jaws fit around two flat parallel sides of a rotary fastener, allowing it to be turned. The spanner head is usually set at a 15 degree angle, allowing a wider turning arc. This type of wrench is versatile and can be used on a variety of different fasteners.

A spanner is a type of wrench used to tighten or loosen nuts and bolts. There are many different types of spanners, each with a different purpose. Open end spanners have one open end and one closed end. Double end spanners have two open ends. Ring spanners have a closed loop at one end. Socket spanners have a socket at one end. Box spanners have a closed end and a box-shaped opening at the other end. Combination spanners are a combination of two or more of the above types. Hook spanners have a hook-shaped end. Adjustable spanners have an adjustable jaw that can be opened or closed to fit a variety of sizes.

Warp Up

There is no definitive answer to this question, as the appropriate spanner size will depend on a variety of factors, including the type and size of the bolt or nut being tightened or loosened, the amount of torque required, and the level of precision needed. In general, however, it is advisable to err on the side of a larger spanner size, as this will provide more leverage and make it easier to apply the required torque.

There is no definitive answer when it comes to determining spanner size. However, there are a few general tips that can be followed in order to ensure that you choose the right size spanner for the job. Firstly, it is important to take into account the bolt or nut that you are trying to loosen or tighten. The spanner size should be based on the width of the nut or bolt, not the size of the hole. Secondly, it is also important to consider the amount of space that you have to work with. If you are working in a confined space, then you may need to opt for a smaller spanner size in order to avoid any issues. Finally, it is also worth bearing in mind that different materials will require different spanner sizes. For example, softer metals will require a smaller spanner size than harder metals. By taking all of these factors into account, you can help to ensure that you choose the right spanner size for the job.