Screwdriver handles are made by combining different materials into a single unit. The handle is typically made from a variety of plastics, while the metal band that goes around the outside is usually made from steel. This combination of materials makes for a strong and durable handle that can withstand a lot of force.

The screwdriver handle is made from a plastic or metal rod that is inserted into the end of the screwdriver shaft. The rod is then twisted to create a spiral that runs the length of the shaft. This spiral creates a series of grooves that allow the screwdriver to grip the screw more securely.

How is a screwdriver handle manufactured?

Cellulose acetate is a type of plastic that is commonly used to make the handles of screwdrivers. It is delivered to factories in powder form and then mixed with a liquid plasticizer in a giant blender. This mixture is then used to create the handles of screwdrivers.

Clear plastic screwdriver handles are usually made from cellulose acetate butyrate, a material developed in the 1930s. Its primary component (cellulose acetate) is made by reacting the cellulose from wood pulp with a variety of acids.

What kind of materials are most screwdriver handles made of

The screwdriver handle is a very important part of the tool, and there are a few things to consider when choosing one. The most important factor is probably comfort, as you will be holding the handle while using the screwdriver. An ergonomic handle is a good choice, as it will be easier to grip and will reduce fatigue. The material of the handle is also important. Hard plastics like cellulose acetate are durable and easy to clean, but they can be slippery. Soft materials like thermoplastic rubber provide a better grip, but they may not be as durable.

The handle of an electrician’s screwdriver is made of plastic to protect the electrician from electric shock while working with a live wire.

How are handles manufactured?

Injection molding is one of the most popular manufacturing methods for plastic products. It is versatile and molds can be designed as per the client’s requirements. Plastic is melted and poured into a mold and then allowed to cool to get the desired shape and size. Injection molding is used to produce a wide variety of products, from simple objects like bottle caps and toothbrushes to more complex products like car parts and medical devices.

Vacuum forming is another popular manufacturing method for plastic products. In this process, a sheet of plastic is heated until it is soft and then placed over a mold. The mold is then placed in a vacuum chamber, which sucks the plastic sheet tight against the mold. The plastic cools and hardens, taking on the shape of the mold. Vacuum forming is typically used to make larger objects, such as car body panels and boat hulls.

Rotational molding is a third manufacturing method for plastics. In this process, a mold is filled with plastic powder and then placed in a oven. The mold is rotated slowly in the oven, which melts the plastic and coats the inside of the mold. The mold is then cooled, and the plastic solidifies, taking on the shape of the mold. Rot

Tubular hydroforming is a great manufacturing method for producing case handles that have a desired shape. In this process, the work part is inserted into a mold and pressurized water is used to shape the part into the desired shape, either solely from the inside or with outside pressure applied at the same time. This is a great way to produce case handles that are both strong and have a desired shape.

Why do screwdriver handles have ridges?

It’s important to have a good grip on your screwdriver handle to prevent the tool from slipping and to ensure accuracy while working. Look for a handle that is comfortable to hold and that won’t slip out of your hand easily.

The problem with old toolbox handles is that they start releasing butyric acid and free acetic acid. Butyric acid, in particular, smells like smelly socks. It’s a carboxylic acid, and the bad part is that it migrates within your confined toolbox, which means other tools absorb some of that nasty stink.

What are Craftsman screwdriver handles made of

This screwdriver set is perfect for any handyman or woman. The set includes a variety of screwdrivers to handle any task, big or small. The acetate handle is durable and comfortable to grip, and the steel construction with satin-nickle finish is built to last.

And basically what you do is I dampen a rag slightly Shake this up a little bit And up just a light mist of water You’re going to slightly dampen your work surface As you can see, it’s already starting to bead up And that’s what you want So, I’m just going to do a light misting Just to show you And you can see the water beading up Just lightly run your finger over it And that’s all you’re going to do So, the water’s just going to help the paint to flow out Nice and evenly When you’re done, you just want to take a dry rag And just lightly go over the top just to remove any excess water And that’s it

What plastic is used for tool handles?

Plastisol is a compound made up of polyvinyl chloride (PVC) and plasticizers. It is typically used to create a flexible and stretchy coating. The coating is applied by dipping preheated tool handles into the plastisol. The temperature of the tool mainly determines how thick the coating will be.

There are many benefits to using FRP for tool handles. FRP is lightweight, strong, and durable. It is also resistant to rot and insects. FRP handles are also comfortable to grip and are less likely to cause blisters than other materials.

Why are screwdriver made up of wooden or plastic handles

The screwdriver used by the electrician has a plastic or a wooden handle because the front portion of the screwdriver is made up of iron which is a good conductor of heat and electricity, so to prevent electric shock the handles are made of nonmetals such wood and plastic as they are insulator. This is why the handle needs to be made of a non-conducting material.

Thank you for your question!

Plastic or wood is indeed a poor conductor of heat, which makes it an ideal material for cooking utensils. The heat is not transferred easily to the handles, so they remain cool to the touch. This allows us to hold the utensil easily without fear of burning ourselves.

What is the most common mistake made in using screwdrivers?

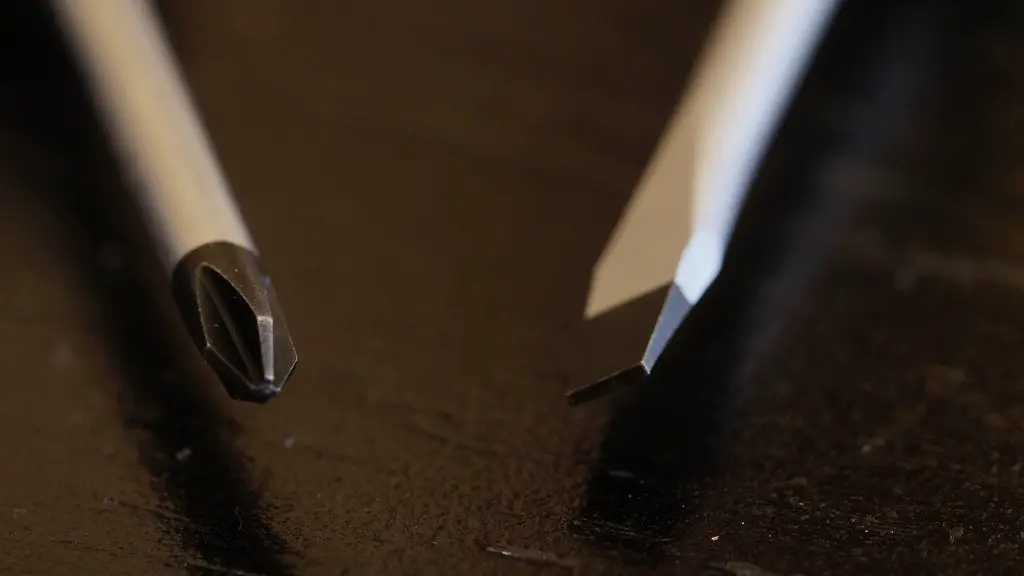

The most common mistake people make when using a screwdriver is choosing the wrong type for the job. As a result, they either strip the screw, making it difficult to remove if they need to, or they damage a perfectly good screwdriver. Be sure to select the appropriate screwdriver for the job at hand to avoid these issues.

There are four main types of manufacturing processes for metal handles: stamping, machining, casting, and forging. Chinese manufacturers often use different methods to produce metal handles, depending on the desired results. Once the components have been produced, the products are machined to match your exact specifications.

Conclusion

There isn’t a single answer to this question as there are many different ways to make a screwdriver handle. However, some of the most common methods include molding the handle out of plastic or metal, or carving it out of wood.

A screwdriver handle is typically made from a durable, sturdy material like plastic or metal. The material is then formed into the desired shape and size for the handle. Once the handle is formed, a hole is bored into the center of it so that the shaft of the screwdriver can be inserted. The handle is then placed onto the shaft and secured in place with a set screw.